Dairy Industry

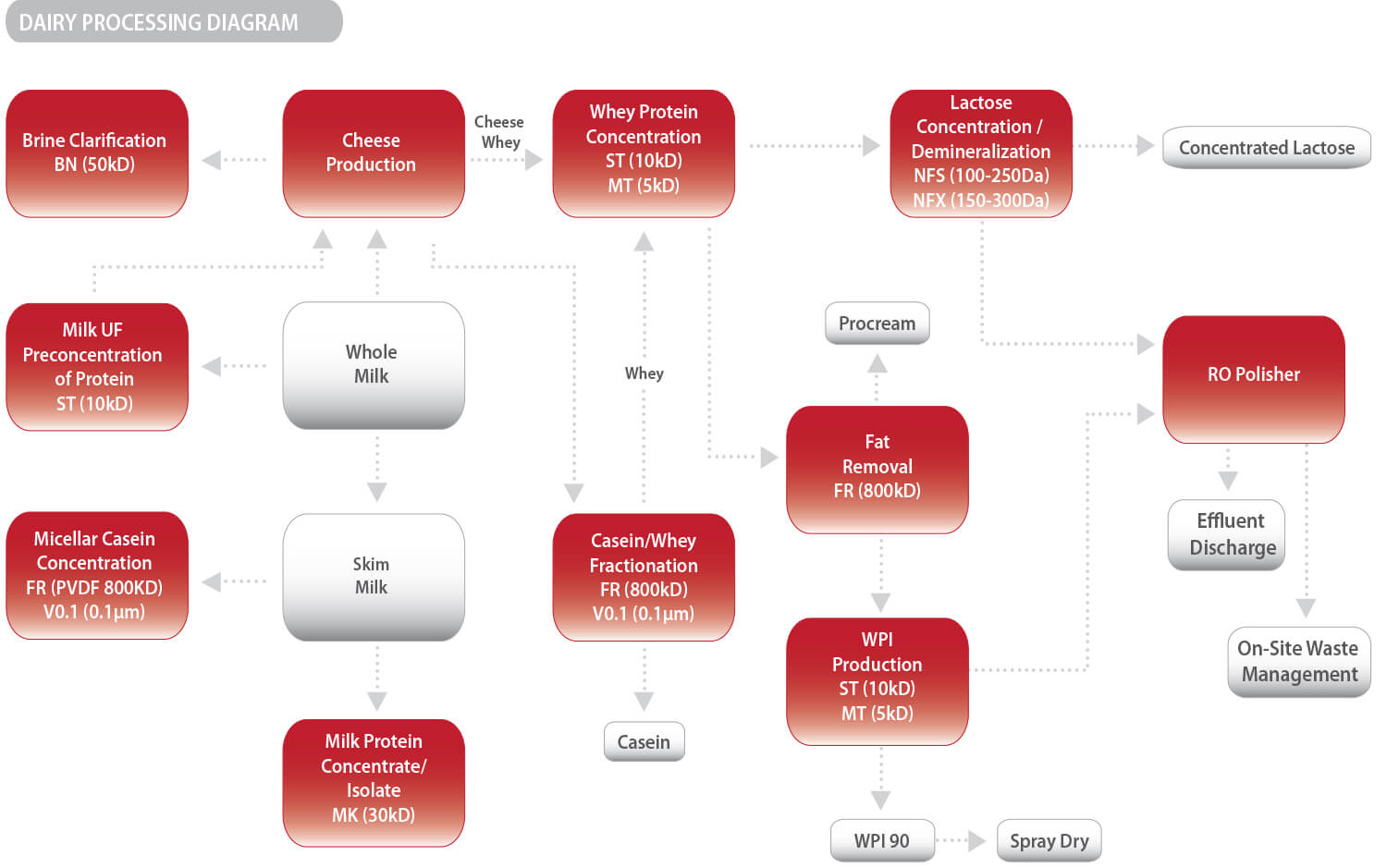

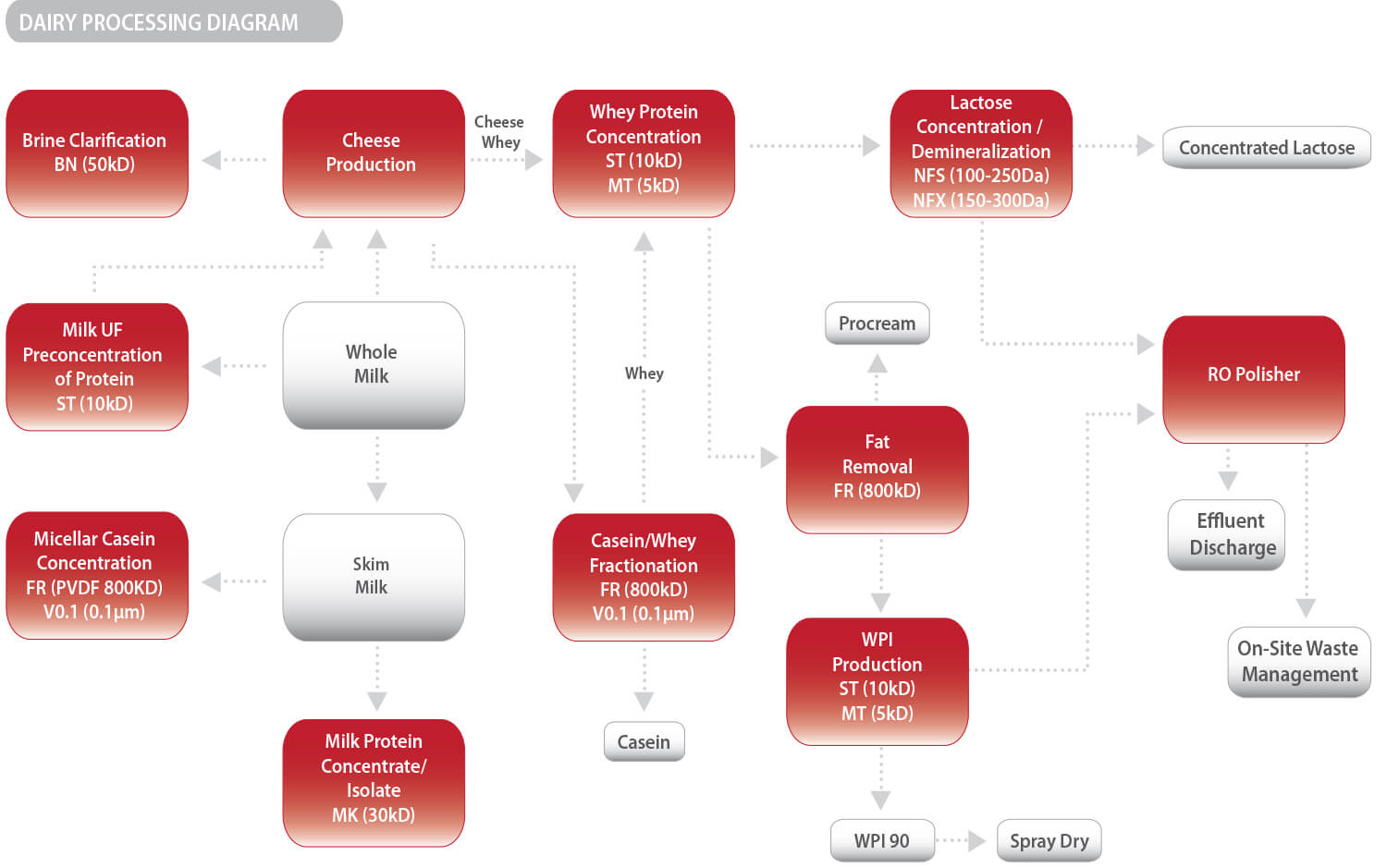

With almost 25 years of experience, Synder Filtration has proven to be one of the top suppliers of membrane technology throughout the dairy industry. As a manufacturer of both membranes and systems, we strive to provide quality products and reliable service for our customers around the world. Our ultrafiltration line of elements has gradually expanded over the years, to contain one of the most extensive pore size ranges available for use in applications such as whey protein concentration, milk protein isolation, and cheese brine clarification. For these reasons, we take pride in fully understanding the needs of our customers in order to produce membranes and systems suitable for their separation needs.

Lactose Concentration and Demineralization

Lactose Concentration and Demineralization

Nanofiltration is widely used throughout the dairy industry for lactose concentration and demineralization. By allowing monovalent ions to pass through while partially rejecting multivalent ions, whey volume can be further reduced in order to attain savings in transportation costs. The crystallization process can also benefit from the use of nanofiltration beforehand, by reducing the amount of minerals present to product higher-quality lactose from the whey and permeate.

With traditional nanofiltration membranes having typically 98% MgSO4 rejection, Synder’s NFS & NFX NF membranes push the boundaries with an astounding >99% MgSO4 rejection. This results in a very high retention of lactose, making it ideal for lactose concentration.

CASE STUDY – NF Lactose Concentration and Demineralization

Overview

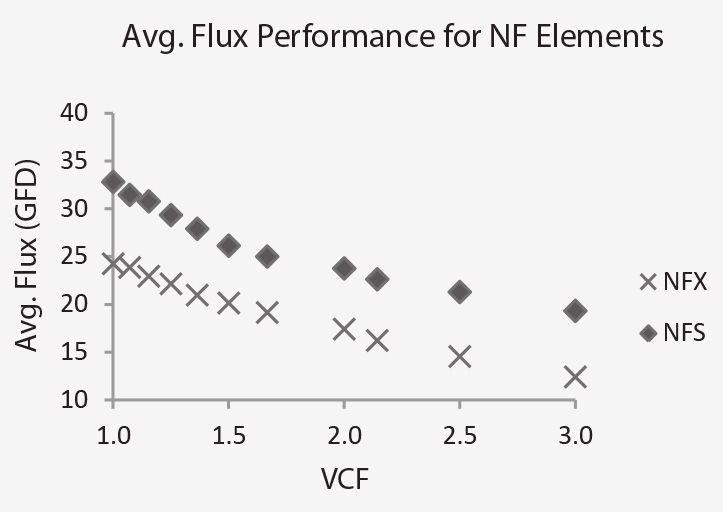

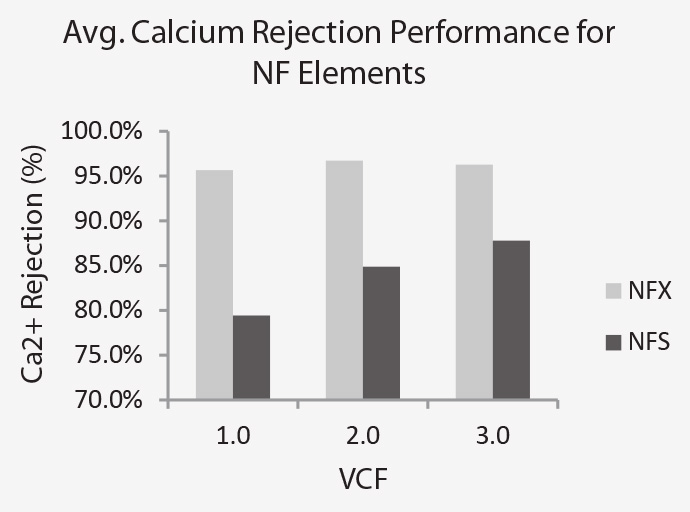

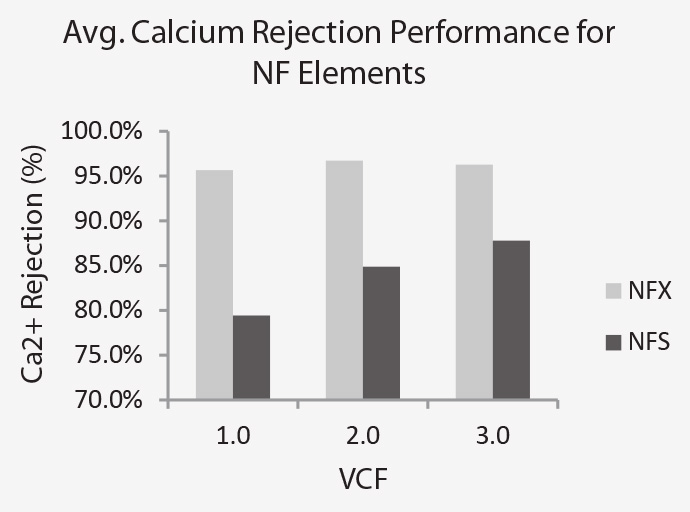

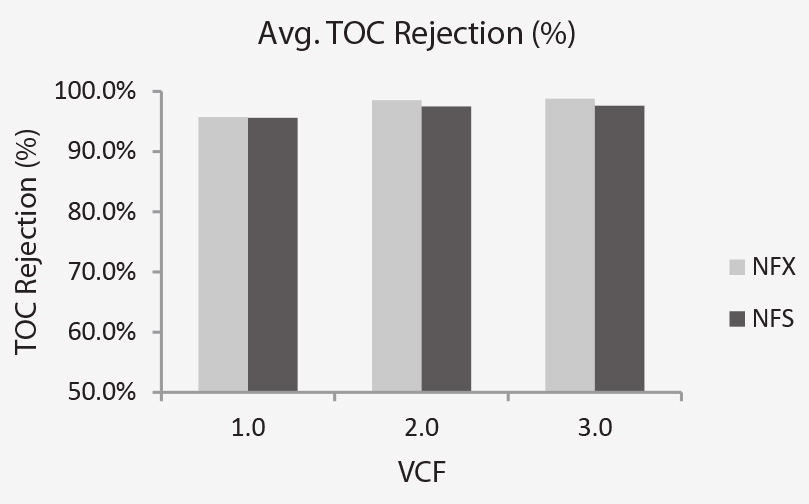

The objective of this study was to examine the flux, total organic carbon (TOC) rejection, and calcium rejection performance of Synder’s NFX and NFS membranes, with acid whey UF permeate used as the incoming feed stream. These results will determine the potential for NFS to be used in the dairy industry for applications such as lactose concentration and demineralization, with specific focus on calcium removal.

Figure 1: Average calcium rejection performance for Synder’s NFX and NFS 2540 elements obtained up to 3x VCF.

Figure 1: Average calcium rejection performance for Synder’s NFX and NFS 2540 elements obtained up to 3x VCF.

Experimental

Two independent trials were tested with Synder’s NFX and NFS membranes in 2540 spiral wound element modules. Acid whey UF permeate generated from Synder’s ST 2540 spiral wound elements was used as the incoming feed stream. Elements were tested at 440 psi with a feed flow rate of 2 gpm at 25°C. Permeate flux and calcium rejection was measured from 1x to 3x volumetric concentration factor (VCF).

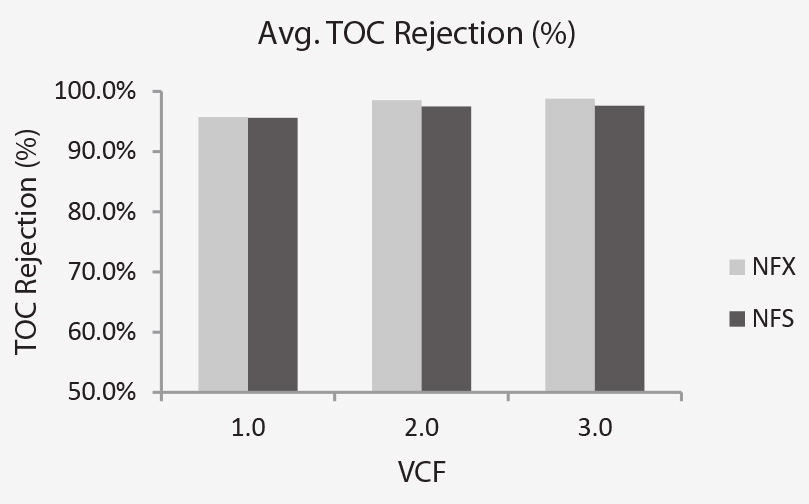

Figure 3: Average TOC rejection performance for Synder’s NFX and NFS 2540 elements obtained up to 3x VCF.

Figure 3: Average TOC rejection performance for Synder’s NFX and NFS 2540 elements obtained up to 3x VCF.

Conclusion

The results of this study indicate that Synder’s NFS membrane shows superior flux and higher calcium passage compared to NFX, in a feed stream composed of acid whey UF permeate.

The considerable difference in calcium rejection performance between the two membrane types shows the benefit for NFS to produce higher-quality lactose.

Whey Protein Concentrate/Isolate Production

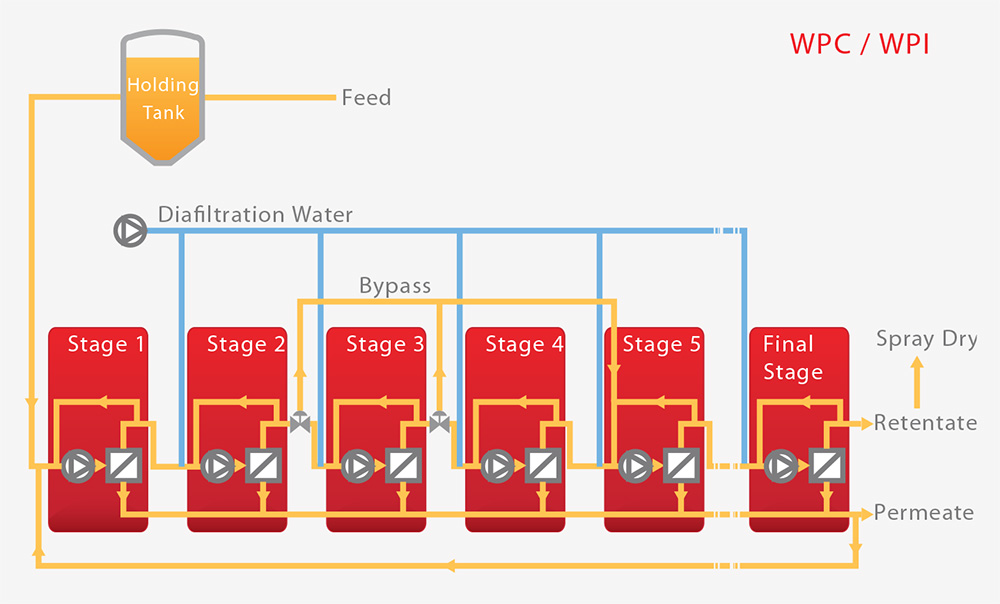

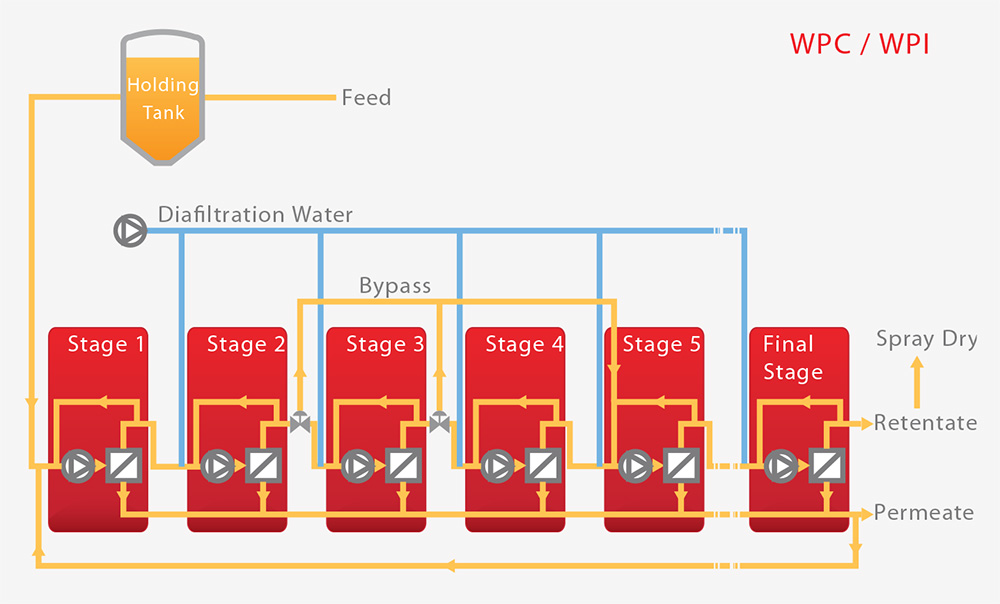

Synder’s polymeric spiral-wound ultrafiltration membranes are standard for the manufacturing of whey protein concentrate and isolate from cheese whey. VT (PES 3), MT (PES 5), and ST (PES 10) ultrafiltration membranes are commonly used in this application to provide an optimal balance of UF protein separation, high flux rates and membrane durability.

For high-protein WPC products, a continuous staged ultrafiltration system is typically set up which includes diafiltration in later stages to wash more small non-protein components into the permeate. In the stage-by-stage configuration, the customer typically increases the spacer size of the element to maximize the solid content during the later stages of the filtration system.

For WPI, microfiltration is a necessary initial step to lower the fat content in whey protein. Ultrafiltration is applied to the MF permeate defatted protein, along with diafiltration for later stages. The resulting WPI product is much higher in whey protein because the fat and lactose content are so low compared to WPC. All Sanitary Series membranes conform to 3-A, FDA, and USDA sanitary standards, and are also Kosher & Halal certified. All PES-based Ultrafiltration MAX membranes and sanitary spiral-wound elements are also compliant with USP Class VI standards.

All Sanitary Series membranes conform to 3-A, FDA, and USDA sanitary standards, and are also Kosher & Halal certified. All PES-based Ultrafiltration MAX membranes and sanitary spiral-wound elements are also compliant with USP Class VI standards.

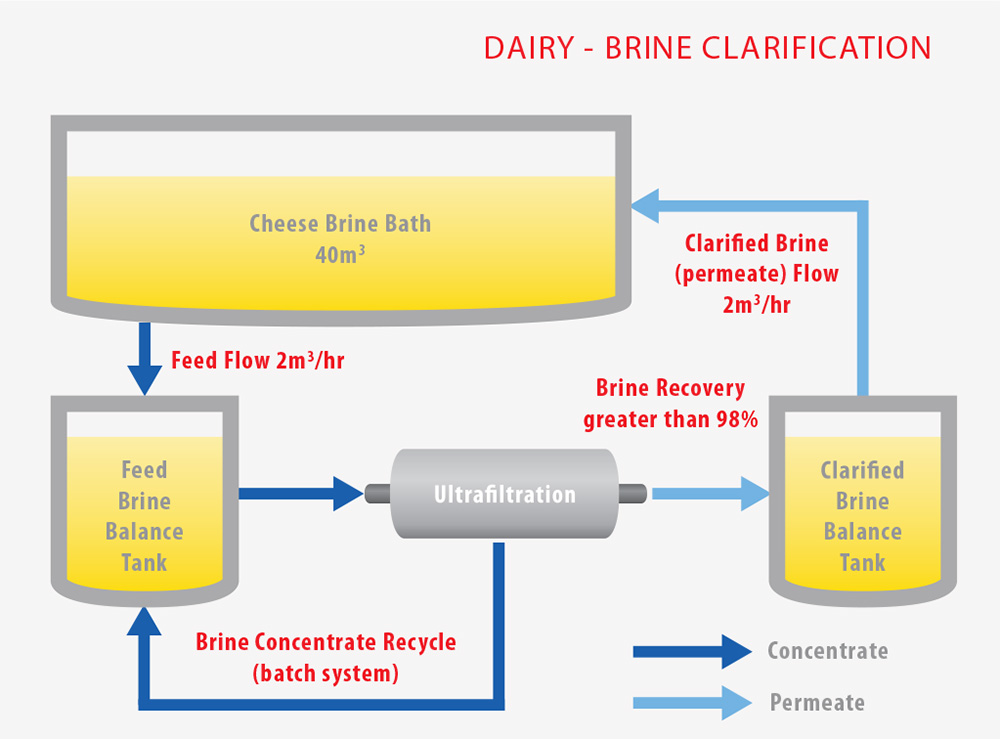

Brine Clarification

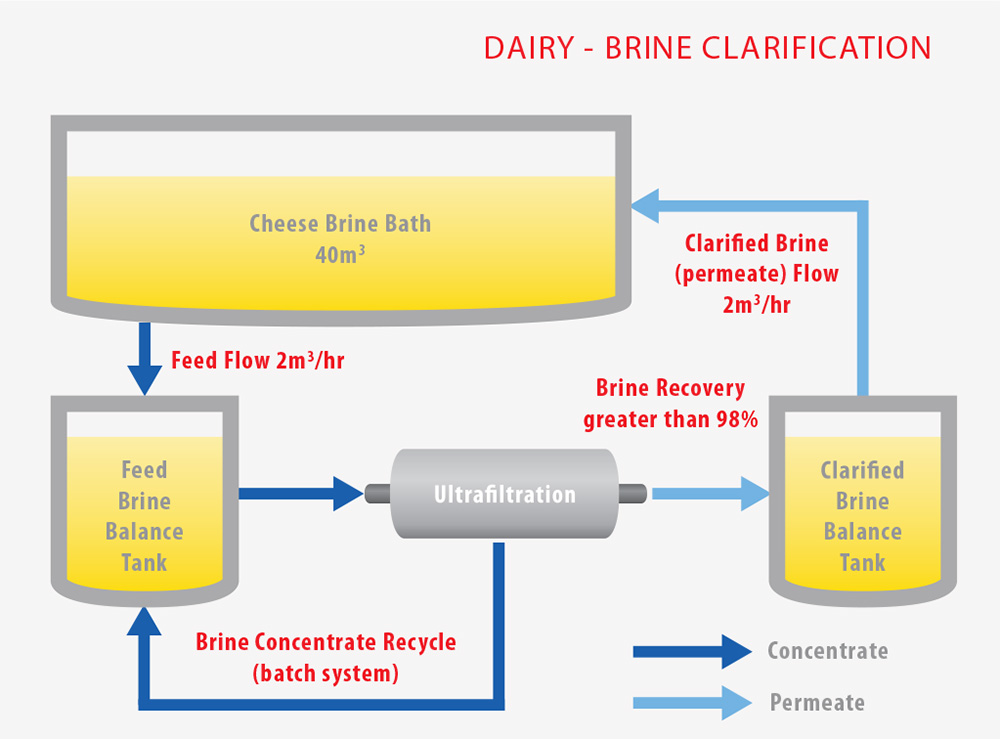

Ultrafiltration is commonly used to clarify brine solutions that salt and chill cheeses like mozzarella and parmesan. This saves costs through the reuse of the brine solution over multiple batches of cheese. Synder’s BN (PVDF 50) membrane is able to clarify these solutions well, in addition to maintaining the trace mineral balance necessary to maintain cheese quality.

In the production of cheese, salt brining is used to add flavor and help preserve the cheese. Filtration clarification allows for cheese fines, residual fat and all microorganisms to be removed for ideal brining to proceed. Salting draws moisture from the cheese in order to form the rind and preserve the cheese. As the challenges for waste effluent disposal continue to rise, the use of brine clarication through ultrafiltration has become increasingly important to minimize costs and reduce environmental issues. Milk Protein Concentrate/Isolate Production

Milk Protein Concentrate/Isolate Production

Developed in 1999, Synder’s MK (PES 30kDa) ultrafiltration membrane was specifically designed for the concentration of milk proteins from skim milk. This membrane is still used today throughout the world for this application stemming from its high performance and stability.

Milk protein concentrates and isolates are manufactured from skim milk through the use of membrane filtration technology. Whole milk is separated into skim milk and cream, and the skim milk is then fractionated using ultrafiltration membranes such as Synder’s MK PES UF membrane to further concentrate the milk protein. The whey and casein blend offer an assortment of nutritional and functional properties, including high levels of calcium, phosphorous, potassium, and magnesium. Milk protein concentrate can also improve the heat stability and solubility of the product it is incorporated into. The bland flavor profile also make it an ideal choice as an additive in products throughout the food and beverage industry, including cheeses, protein bars, yogurts, and baby formula.

MAX Series – High pH & Temperature

Synder also offers a high pH/high temperature “MAX” line of elements available for all ultrafiltration and microfiltration pore sizes. These membranes can be sanitized without the use of chlorine, which can further extend the membrane and equipment life.

CASE STUDY – High Solids Feed Spacer

Overview

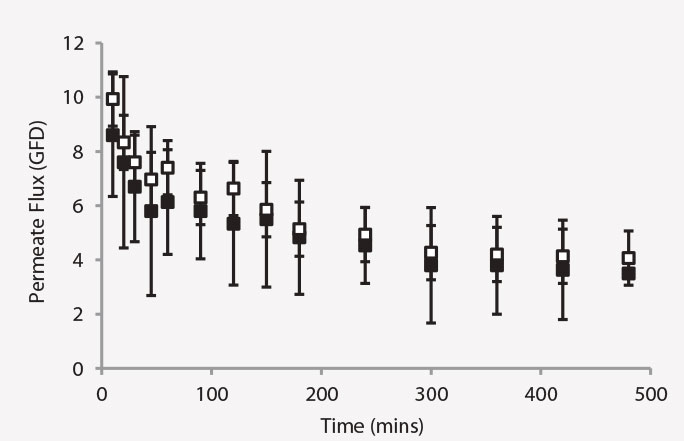

Feed spacer geometry can be just as crucial as spacer thickness in high solids applications, such as whey protein concentration. The objective of this study was to examine differences in flux and pressure drop performance between Synder’s ST (PES 10kDa) elements with standard 80mil diamond and open channel ribbed spacers in order to identify any potential advantages of switching to an open channel ribbed spacer.

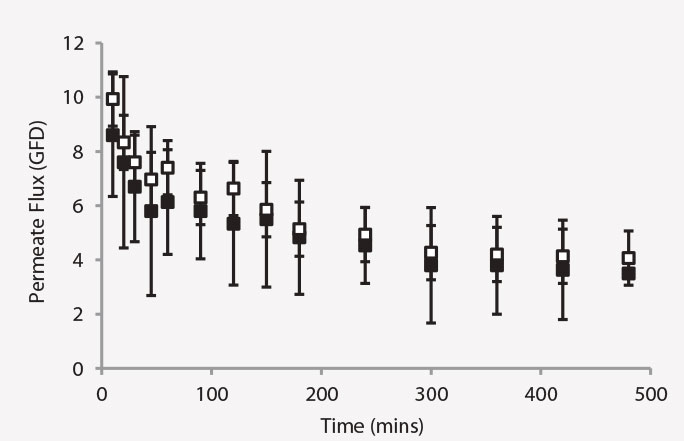

Figure 1. Permeate flux values of ST elements containing diamond net (black square) and

open channel ribbed spacer s(white square). Error bars represent standard deviation of n=3

samples.

Figure 1. Permeate flux values of ST elements containing diamond net (black square) and

open channel ribbed spacer s(white square). Error bars represent standard deviation of n=3

samples.

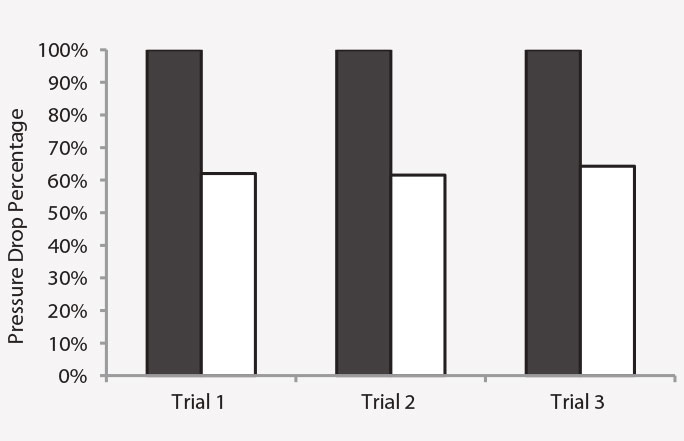

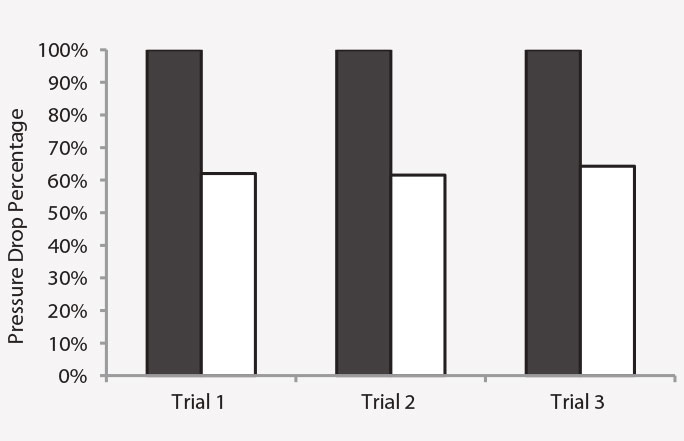

Figure 2 . Pressure drop of ST elements containing diamond net(black square) and

open channel ribbed spacers (white square) expressed as a percent of diamond net

pressure drop .

Figure 2 . Pressure drop of ST elements containing diamond net(black square) and

open channel ribbed spacers (white square) expressed as a percent of diamond net

pressure drop .

Results

Examination of permeate flux trends from three independent trials using a total of 6 elements indicated no significant difference in flux performance between elements containing either of the two spacer types (Figure 1). High protein rejection for all tested elements indicates that the obtained flux values are unlikely to have arisen as a result of a loss of membrane integrity. Despite little difference in flux performance, a more noticeable difference was observed with respect to element pressure differential, where elements containing open channel ribbed spacers showed reduced pressure drop (Table 2). The use of the ribbed spacer showed a reduction in pressure drop of at least 37% across the length of the element (Table 3). The expected pressure drop values for elements with larger diameters were subsequently extrapolated according to open flow channel area and assuming no change in operating conditions.

Conclusion

The data obtained in this study indicates that the use of open channel ribbed spacers may offer distinct advantages over standard diamond spacers in high solid applications such as whey protein concentration. Despite no observable differences in flux performance when challenged with 20% total solids in the form of sweet whey, there was a significant difference between the two configurations with respect to pressure drop, where ribbed spacers showed a calculated pressure drop reduction of 37% compared to diamond net. This allows pumps to deliver the same crossflow rate at lower speeds, resulting in reduced operating costs. When boost pressure is used as a correlation to crossflow rate, it is important to note that the boost pressure should be lowered to obtain a lower pressure drop across the element when switching to elements containing ribbed spacers.

Milk Protein Fractionation/Separation

Whey and casein protein separation are newer and important processes used in the dairy industry. Synder’s FR (PVDF800) and V0.1 MF membranes provide an economically feasible solution for the separation of these valuable proteins.

The use of microfiltration technology for protein fractionation and separation into whey and casein fractions is becoming more common throughout the dairy industry. The large pores in the microfiltration membrane allow most of the whey protein to pass through the membrane and casein to be fractionated before the use of ultrafiltration to further concentrate and purify each protein product. This technique of protein fractionation allows for more options to manufacture unique protein products.

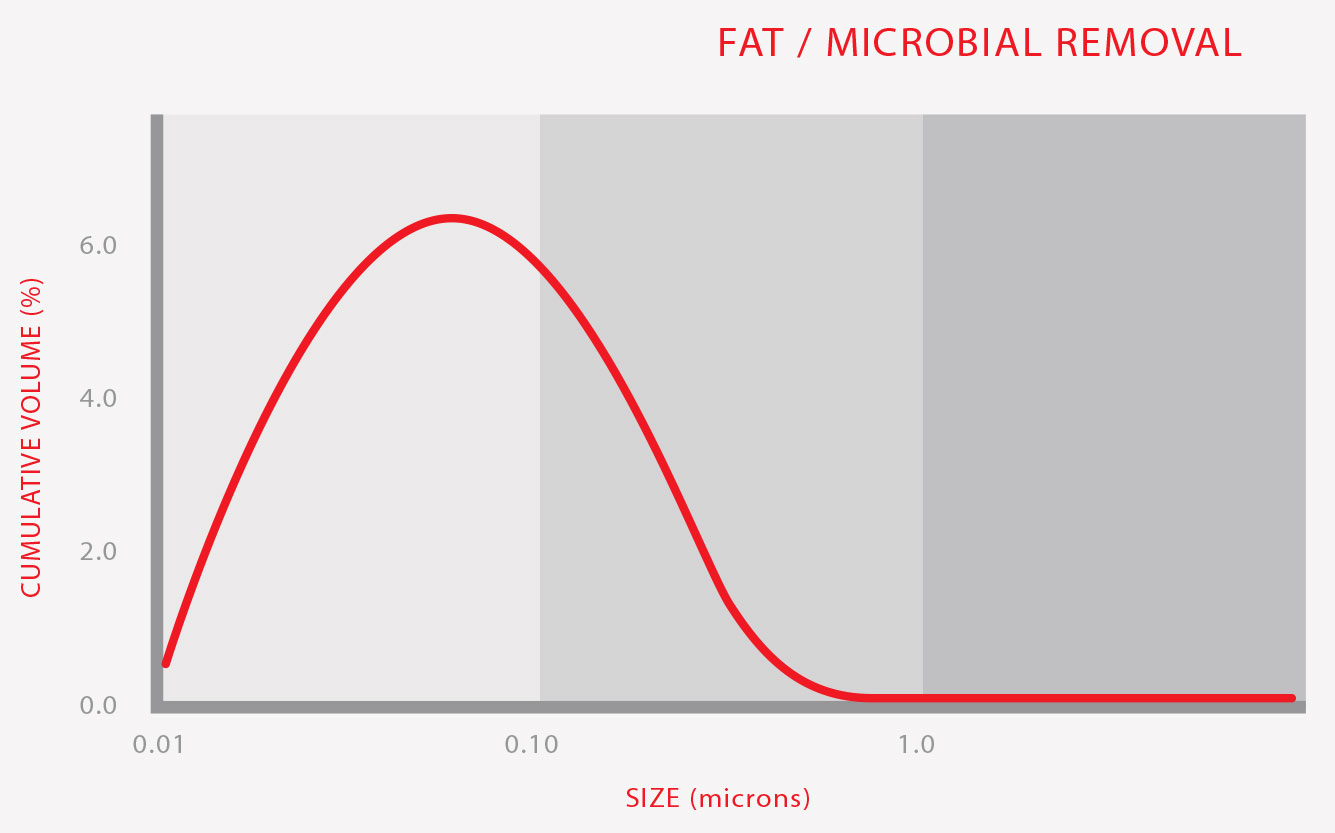

Fat/Microbial Removal

Synder’s FR (PVDF 800), V0.1 & V0.2 MF membranes can be used as the final fat and microbial removal stage in the production of milk in order to produce high quality WPC and WPIs. Our UF systems are able to operate at lower pressures and are typically less expensive to build and operate compared to ceramic membrane systems.

With the largest pore size range, microfiltration is commonly used to extend the shelf-life of milk and produce high-quality milk products. It is especially applicable for use of bacteria and spore removal when treatment options involving high temperature conditions are not suitable. This process can be used as a pretreatment step to pasteurization to ensure that all vegetative spores are completely removed from the milk.

All Sanitary Series membranes conform to 3-A, FDA, and USDA sanitary standards, and are also Kosher & Halal certified.

MAX Series – High pH & Temperature

Synder also offers a high pH/high temperature “MAX” line of elements available for all ultrafiltration and microfiltration pore sizes. These membranes can be sanitized without the use of chlorine, which can further extend the membrane and equipment life.

See Sanitary Catalog for more details.

CASE STUDY – MF for Casein Concentration in Skim Milk

Overview

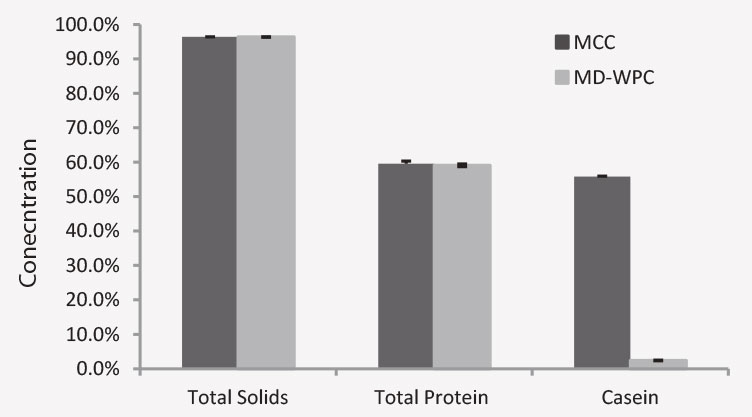

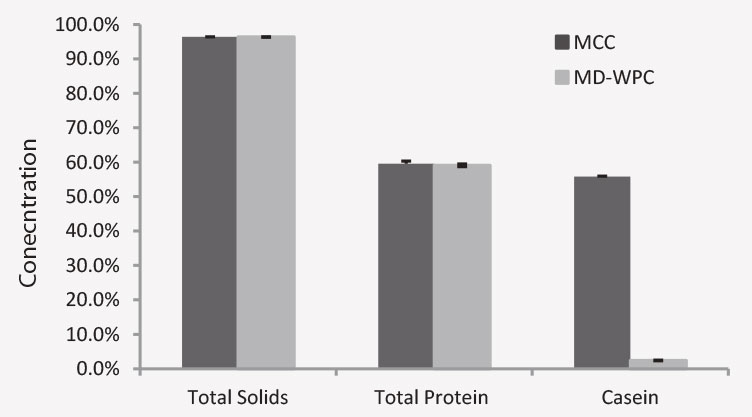

The objective of this study was to increase the fractionation efficiency and purity of the β-casein and milk derived whey protein isolate (MD-WPI) as detailed in the patent issued to UW-Madison Center for Dairy Research. The process utilized Synder’s FR microfiltration (MF) membrane to conduct two critical parts of the process starting from skim milk.

Experimental

All testing was performed at the Wisconsin Center for Dairy Research (WCDR) using Synder FR 8038 elements with 46mil feed spacers, where two elements were operated in parallel. The feed solution was comprised of pasteurized skim milk (Table 1). The MF elements were operated using 12 psi boost pressure at an operating temperature of ≤5°C for the initial fractionation step. Retentates from each type of protein samples (β-casein & MD-WPI) were subsequently spray-dried and analyzed for total solids, protein, and casein concentration.

Figure 1: Total solids, total protein, and casein concentrations in β-casein (black square) and MD-WPI (white square) powder.

Figure 1: Total solids, total protein, and casein concentrations in β-casein (black square) and MD-WPI (white square) powder.

Conclusion

The results of this study indicate that the combined use of MF and diafiltration in the processing of skim milk allows for the production of unique protein products. The ability to produce β-casein and MD-WPI is useful for a wide variety of food and beverage applications. The use of UF permeate for diafiltration not only lessens the water consumption associated with typical diafiltration processes but can also contribute to the stability of the β-casein during fractionation.

CASE STUDY – MF for Fat Removal

Overview

The objective of this study was to examine the flux and fat removal capabilities of Synder’s FR (PVDF 800kDa) Microfiltration membrane.

Experimental

Synder’s FR 2540 spiral wound element module with a 46mil feed spacer was tested in a feed stream of homogenized whole milk. The element was tested at 15 psi with a feed flow rate of 8 gpm at 30-35°C. Permeate flux and fat concentration were tested, with the fat analysis performed by Eurofins DQCI (Mounds View, MN). Table 1 shows the permeate flux measurements, while Table 2 shows the fat concentration in the feed and permeate samples.

Conclusion

The FR membrane was able to easily remove fat from the whole milk feed solution, with fat rejection measuring above 99.5%. Permeate flux was also adequate, at 61 GFD. This data, along with WCDR’s study on FR for casein concentration in skim milk makes the FR membrane highly suitable for these types of applications within the dairy industry.

If you have questions about our products, need help nding the right custom membrane solution for your application, or would like to place an order, please email us at sales@synderfiltration.com or call us at (707) 451-6060.

NANOFILTRATION

Lactose Concentration and Demineralization

Lactose Concentration and DemineralizationNanofiltration is widely used throughout the dairy industry for lactose concentration and demineralization. By allowing monovalent ions to pass through while partially rejecting multivalent ions, whey volume can be further reduced in order to attain savings in transportation costs. The crystallization process can also benefit from the use of nanofiltration beforehand, by reducing the amount of minerals present to product higher-quality lactose from the whey and permeate.

With traditional nanofiltration membranes having typically 98% MgSO4 rejection, Synder’s NFS & NFX NF membranes push the boundaries with an astounding >99% MgSO4 rejection. This results in a very high retention of lactose, making it ideal for lactose concentration.

CASE STUDY – NF Lactose Concentration and Demineralization

Overview

The objective of this study was to examine the flux, total organic carbon (TOC) rejection, and calcium rejection performance of Synder’s NFX and NFS membranes, with acid whey UF permeate used as the incoming feed stream. These results will determine the potential for NFS to be used in the dairy industry for applications such as lactose concentration and demineralization, with specific focus on calcium removal.

Figure 1: Average calcium rejection performance for Synder’s NFX and NFS 2540 elements obtained up to 3x VCF.

Figure 1: Average calcium rejection performance for Synder’s NFX and NFS 2540 elements obtained up to 3x VCF.Experimental

Two independent trials were tested with Synder’s NFX and NFS membranes in 2540 spiral wound element modules. Acid whey UF permeate generated from Synder’s ST 2540 spiral wound elements was used as the incoming feed stream. Elements were tested at 440 psi with a feed flow rate of 2 gpm at 25°C. Permeate flux and calcium rejection was measured from 1x to 3x volumetric concentration factor (VCF).

Table 1: Acid Whey Powder Composition

| Description | Specification |

| Ash | 10.5% max |

| Fat | 1.2 max |

| Moisture | 5.0 max |

| pH | 4.5-5.0 |

| Protein (as is) | 11% min |

| Sediment | 15.0 mg max |

| Titratable Acidity | 0.30% min |

Figure 3: Average TOC rejection performance for Synder’s NFX and NFS 2540 elements obtained up to 3x VCF.

Figure 3: Average TOC rejection performance for Synder’s NFX and NFS 2540 elements obtained up to 3x VCF.Conclusion

The results of this study indicate that Synder’s NFS membrane shows superior flux and higher calcium passage compared to NFX, in a feed stream composed of acid whey UF permeate.

The considerable difference in calcium rejection performance between the two membrane types shows the benefit for NFS to produce higher-quality lactose.

ULTRAFILTRATION

Whey Protein Concentrate/Isolate Production

Synder’s polymeric spiral-wound ultrafiltration membranes are standard for the manufacturing of whey protein concentrate and isolate from cheese whey. VT (PES 3), MT (PES 5), and ST (PES 10) ultrafiltration membranes are commonly used in this application to provide an optimal balance of UF protein separation, high flux rates and membrane durability.

For high-protein WPC products, a continuous staged ultrafiltration system is typically set up which includes diafiltration in later stages to wash more small non-protein components into the permeate. In the stage-by-stage configuration, the customer typically increases the spacer size of the element to maximize the solid content during the later stages of the filtration system.

For WPI, microfiltration is a necessary initial step to lower the fat content in whey protein. Ultrafiltration is applied to the MF permeate defatted protein, along with diafiltration for later stages. The resulting WPI product is much higher in whey protein because the fat and lactose content are so low compared to WPC.

All Sanitary Series membranes conform to 3-A, FDA, and USDA sanitary standards, and are also Kosher & Halal certified. All PES-based Ultrafiltration MAX membranes and sanitary spiral-wound elements are also compliant with USP Class VI standards.

All Sanitary Series membranes conform to 3-A, FDA, and USDA sanitary standards, and are also Kosher & Halal certified. All PES-based Ultrafiltration MAX membranes and sanitary spiral-wound elements are also compliant with USP Class VI standards.Brine Clarification

Ultrafiltration is commonly used to clarify brine solutions that salt and chill cheeses like mozzarella and parmesan. This saves costs through the reuse of the brine solution over multiple batches of cheese. Synder’s BN (PVDF 50) membrane is able to clarify these solutions well, in addition to maintaining the trace mineral balance necessary to maintain cheese quality.

In the production of cheese, salt brining is used to add flavor and help preserve the cheese. Filtration clarification allows for cheese fines, residual fat and all microorganisms to be removed for ideal brining to proceed. Salting draws moisture from the cheese in order to form the rind and preserve the cheese. As the challenges for waste effluent disposal continue to rise, the use of brine clarication through ultrafiltration has become increasingly important to minimize costs and reduce environmental issues.

Milk Protein Concentrate/Isolate Production

Milk Protein Concentrate/Isolate ProductionDeveloped in 1999, Synder’s MK (PES 30kDa) ultrafiltration membrane was specifically designed for the concentration of milk proteins from skim milk. This membrane is still used today throughout the world for this application stemming from its high performance and stability.

Milk protein concentrates and isolates are manufactured from skim milk through the use of membrane filtration technology. Whole milk is separated into skim milk and cream, and the skim milk is then fractionated using ultrafiltration membranes such as Synder’s MK PES UF membrane to further concentrate the milk protein. The whey and casein blend offer an assortment of nutritional and functional properties, including high levels of calcium, phosphorous, potassium, and magnesium. Milk protein concentrate can also improve the heat stability and solubility of the product it is incorporated into. The bland flavor profile also make it an ideal choice as an additive in products throughout the food and beverage industry, including cheeses, protein bars, yogurts, and baby formula.

MAX Series – High pH & Temperature

Synder also offers a high pH/high temperature “MAX” line of elements available for all ultrafiltration and microfiltration pore sizes. These membranes can be sanitized without the use of chlorine, which can further extend the membrane and equipment life.

CASE STUDY – High Solids Feed Spacer

Overview

Feed spacer geometry can be just as crucial as spacer thickness in high solids applications, such as whey protein concentration. The objective of this study was to examine differences in flux and pressure drop performance between Synder’s ST (PES 10kDa) elements with standard 80mil diamond and open channel ribbed spacers in order to identify any potential advantages of switching to an open channel ribbed spacer.

Figure 1. Permeate flux values of ST elements containing diamond net (black square) and

open channel ribbed spacer s(white square). Error bars represent standard deviation of n=3

samples.

Figure 1. Permeate flux values of ST elements containing diamond net (black square) and

open channel ribbed spacer s(white square). Error bars represent standard deviation of n=3

samples. Figure 2 . Pressure drop of ST elements containing diamond net(black square) and

open channel ribbed spacers (white square) expressed as a percent of diamond net

pressure drop .

Figure 2 . Pressure drop of ST elements containing diamond net(black square) and

open channel ribbed spacers (white square) expressed as a percent of diamond net

pressure drop .

Table 1 : Feed composition and operating parameters

| Feed Solution | |

| Material | Kraft Foods Global, Sweet Whey |

| Sweet Whey Concentration | 20wt% |

| Synder Membrane | |

| Elements | ST-5B-2540M (Standard Diamond) ST-5PB -2540M ( Ribbed Spacer ) |

| Membrane | 10kDa Polyethersulfone |

| Operating Parameters | |

| Pressure (PSI) | 120 |

| Crossflow Rate (GPM) | 4 |

| Temperature (C) | 25 |

| Table 2: Average recorded ΔP and protein rejection values for each run. | ||||||||

| Element Model | Spacer Type |

|

||||||

| ST-5B-2540M | 80mil Diamond |

|

||||||

| ST-5PB-2540M | 80mil Ribbed |

|

||||||

| Table 3. Calculated pressure drop reductions between 2540 elements with diamond and open channel ribbed spacers. | |||||||

| Spacer Type |

|

||||||

| 80mil Diamond |

|

||||||

| 80mil Ribbed |

|

||||||

| Pressure Drop Reduction |

|

||||||

| Average Pressure Drop Reduction | 37% | ||||||

Results

Examination of permeate flux trends from three independent trials using a total of 6 elements indicated no significant difference in flux performance between elements containing either of the two spacer types (Figure 1). High protein rejection for all tested elements indicates that the obtained flux values are unlikely to have arisen as a result of a loss of membrane integrity. Despite little difference in flux performance, a more noticeable difference was observed with respect to element pressure differential, where elements containing open channel ribbed spacers showed reduced pressure drop (Table 2). The use of the ribbed spacer showed a reduction in pressure drop of at least 37% across the length of the element (Table 3). The expected pressure drop values for elements with larger diameters were subsequently extrapolated according to open flow channel area and assuming no change in operating conditions.

Conclusion

The data obtained in this study indicates that the use of open channel ribbed spacers may offer distinct advantages over standard diamond spacers in high solid applications such as whey protein concentration. Despite no observable differences in flux performance when challenged with 20% total solids in the form of sweet whey, there was a significant difference between the two configurations with respect to pressure drop, where ribbed spacers showed a calculated pressure drop reduction of 37% compared to diamond net. This allows pumps to deliver the same crossflow rate at lower speeds, resulting in reduced operating costs. When boost pressure is used as a correlation to crossflow rate, it is important to note that the boost pressure should be lowered to obtain a lower pressure drop across the element when switching to elements containing ribbed spacers.

MICROFILTRATION

Milk Protein Fractionation/Separation

Whey and casein protein separation are newer and important processes used in the dairy industry. Synder’s FR (PVDF800) and V0.1 MF membranes provide an economically feasible solution for the separation of these valuable proteins.

The use of microfiltration technology for protein fractionation and separation into whey and casein fractions is becoming more common throughout the dairy industry. The large pores in the microfiltration membrane allow most of the whey protein to pass through the membrane and casein to be fractionated before the use of ultrafiltration to further concentrate and purify each protein product. This technique of protein fractionation allows for more options to manufacture unique protein products.

Fat/Microbial Removal

Synder’s FR (PVDF 800), V0.1 & V0.2 MF membranes can be used as the final fat and microbial removal stage in the production of milk in order to produce high quality WPC and WPIs. Our UF systems are able to operate at lower pressures and are typically less expensive to build and operate compared to ceramic membrane systems.

With the largest pore size range, microfiltration is commonly used to extend the shelf-life of milk and produce high-quality milk products. It is especially applicable for use of bacteria and spore removal when treatment options involving high temperature conditions are not suitable. This process can be used as a pretreatment step to pasteurization to ensure that all vegetative spores are completely removed from the milk.

All Sanitary Series membranes conform to 3-A, FDA, and USDA sanitary standards, and are also Kosher & Halal certified.

MAX Series – High pH & Temperature

Synder also offers a high pH/high temperature “MAX” line of elements available for all ultrafiltration and microfiltration pore sizes. These membranes can be sanitized without the use of chlorine, which can further extend the membrane and equipment life.

See Sanitary Catalog for more details.

CASE STUDY – MF for Casein Concentration in Skim Milk

Overview

The objective of this study was to increase the fractionation efficiency and purity of the β-casein and milk derived whey protein isolate (MD-WPI) as detailed in the patent issued to UW-Madison Center for Dairy Research. The process utilized Synder’s FR microfiltration (MF) membrane to conduct two critical parts of the process starting from skim milk.

Experimental

All testing was performed at the Wisconsin Center for Dairy Research (WCDR) using Synder FR 8038 elements with 46mil feed spacers, where two elements were operated in parallel. The feed solution was comprised of pasteurized skim milk (Table 1). The MF elements were operated using 12 psi boost pressure at an operating temperature of ≤5°C for the initial fractionation step. Retentates from each type of protein samples (β-casein & MD-WPI) were subsequently spray-dried and analyzed for total solids, protein, and casein concentration.

Table 1: Composition of skim milk used in this study

Table 2: Comparison of casein concentration of total protein in spray-dried powders

| Description | Specification |

| Total Solids | 8.9% |

| True Protein | 3.1% |

| Casein | 2.5% |

Table 2: Comparison of casein concentration of total protein in spray-dried powders

| Sample | Casein % of Total Protein |

| β-casein | 83 |

| MD-WPI | 11 |

Figure 1: Total solids, total protein, and casein concentrations in β-casein (black square) and MD-WPI (white square) powder.

Figure 1: Total solids, total protein, and casein concentrations in β-casein (black square) and MD-WPI (white square) powder.Conclusion

The results of this study indicate that the combined use of MF and diafiltration in the processing of skim milk allows for the production of unique protein products. The ability to produce β-casein and MD-WPI is useful for a wide variety of food and beverage applications. The use of UF permeate for diafiltration not only lessens the water consumption associated with typical diafiltration processes but can also contribute to the stability of the β-casein during fractionation.

CASE STUDY – MF for Fat Removal

Overview

The objective of this study was to examine the flux and fat removal capabilities of Synder’s FR (PVDF 800kDa) Microfiltration membrane.

Experimental

Synder’s FR 2540 spiral wound element module with a 46mil feed spacer was tested in a feed stream of homogenized whole milk. The element was tested at 15 psi with a feed flow rate of 8 gpm at 30-35°C. Permeate flux and fat concentration were tested, with the fat analysis performed by Eurofins DQCI (Mounds View, MN). Table 1 shows the permeate flux measurements, while Table 2 shows the fat concentration in the feed and permeate samples.

Table 1: Permeate Flux Measurements

| Sample | Flux (GFD) |

| Permeate Flux | 61 |

Table 2: Fat Concentration Measurements

| Sample | Fat Concentration (%) |

| Feed | 3.09 |

| Permeate | <0.01 |

Conclusion

The FR membrane was able to easily remove fat from the whole milk feed solution, with fat rejection measuring above 99.5%. Permeate flux was also adequate, at 61 GFD. This data, along with WCDR’s study on FR for casein concentration in skim milk makes the FR membrane highly suitable for these types of applications within the dairy industry.

If you have questions about our products, need help nding the right custom membrane solution for your application, or would like to place an order, please email us at sales@synderfiltration.com or call us at (707) 451-6060.

questions? Fill out this form. We’ll contact you within 24 hours!

CASE STUDY

Applications

Resources

MEMBRANE RESOURCES

- Definition of a Membrane

- Membrane Materials: Organic vs. Inorganic

- Pressure-Driven Membrane Filtration Processes

- Concentration Polarization in Pressure-Driven Processes

- Degrees of Membrane Separation

- Flux Behavior in Membrane Processes

Module Configurations & Processes

-> View all membrane resourcesTUTORIALS