![]() Tech CELLTM

Tech CELLTM

Synder Filtration’s TechCELLTM anode cell was specifically designed to optimize the electrocoating process. The tubular anode cell design is the preferred style for smaller industrial E-Coat lines.

TUBULAR CELL FEATURES AND BENEFITS

- More throw angles

- Larger membrane area, longer life leading to lower capital & operating costs

- Built – in cleaning mechanism

- Easy to use & maintain

- Flexibility for your tank

- Custom designs for different tanks and configurations

- Roof cells & hollow cells available

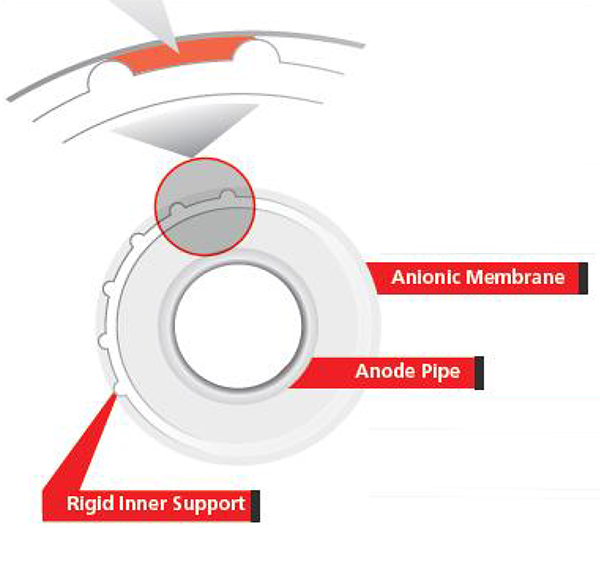

CROSS SECTION OF MEMBRANE SHELL

Annular space between membrane and inner support greatly improves rinsing of membrane to reduce foulants, such as iron oxide. This in turn minimizes build up of electrical resistance on the membrane.

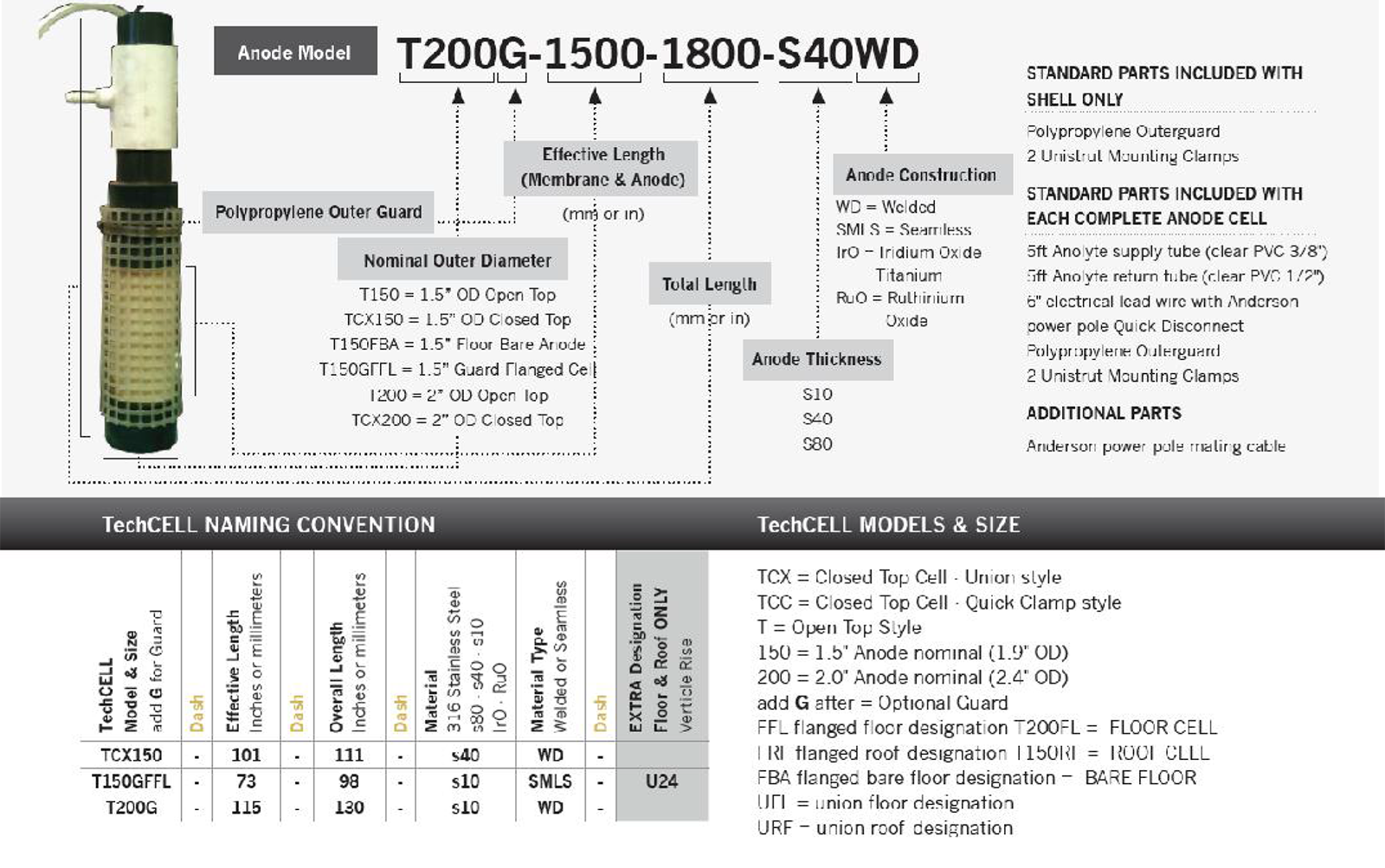

ANODE CELL EXAMPLE

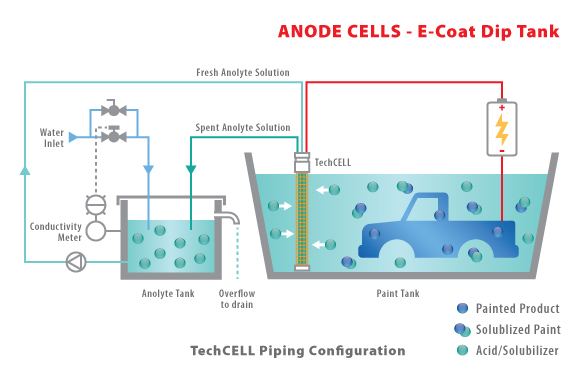

ANOLYTE RECIRCULATION SYSTEM

Synder Filtration’s Anolyte Recirculation System offers advanced conductivity controllers, ultrasonic level sensors, and UV systems to meet the needs of both automotive and industrial E-Coat applications. These can be customized to fit your specific requirements.

WHAT IT DOES

Anolyte cells serve as an opposing electrode for the part being painted, as well as an acid removal device

HOW IT WORKS

Equipped with a robust anionic membrane, the electrical charge on these cells transport the excess acid in the paint bath to an anolyte recirculation system.

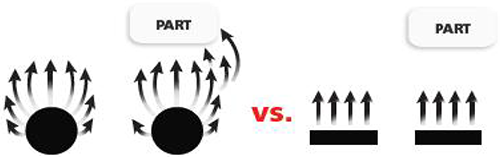

BETTER THROW ANGLES

Tubular (Round) Anodes offer a greater range of electrical “throw angles” vs. flat cells. A greater variety of throw angles can significantly improve the coating quality and coverage in hard to reach areas of the part.

More throw angles also allow the anode to start painting sooner in monorail systems.

Applications

questions? Fill out this form. We’ll contact you within 24 hours!

Resources

MEMBRANE RESOURCES

- Definition of a Membrane

- Membrane Materials: Organic vs. Inorganic

- Pressure-Driven Membrane Filtration Processes

- Concentration Polarization in Pressure-Driven Processes

- Degrees of Membrane Separation

- Flux Behavior in Membrane Processes

Module Configurations & Processes

-> View all membrane resourcesTUTORIALS