Capillary Filtration

Description

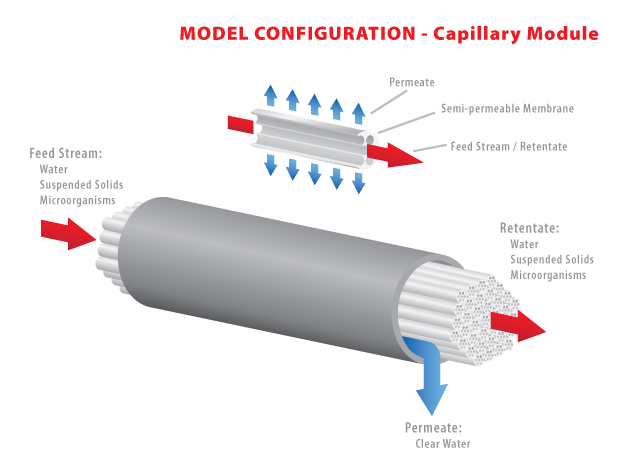

Capillary filtration works on the same basis as tubular filtration, utilizing cross flow as opposed to dead end. The only difference is that the tubes in capillary filtration are smaller, like a capillary, than those used in tubular filtration.How it works

An outer body called a shell is packed full of small tube-like structures akin to capillaries. Water flows across the inside of the capillary tubes and travels through the pores in the capillaries, exiting through the top of the shell as permeate. As the water travels down the capillary length, it exits the other size of the capillary tube as concentrate.Disadvantages

Capillary filtration suffers from the same problems as tubular, though these issues are not as extreme because of the smaller size. Since capillary tubes are only slightly smaller, packing density is still an issue. Because of the decreased size as well, fouling is more likely to occur. Rigidity and strength are not as high as tubular filtration units as well.Advantages

Capillary filtration sacrifices some of the rigidity gained from a large structure for increased packing density. This offers some advantages over tubular modules where support and/or durability are not key factors. The packing density is greater than tubular modules but less than hollow fiber and spiral wound elements.

*Please note that Synder Filtration only offers flat sheet and spiral-wound element configurations. The information above is for comparison purposes only. Please contact us at sales@synderfiltration.com or 7077-451-6060 for more information on pricing and availability.

CASE STUDY

Applications

Resources

MEMBRANE RESOURCES

- Definition of a Membrane

- Membrane Materials: Organic vs. Inorganic

- Pressure-Driven Membrane Filtration Processes

- Concentration Polarization in Pressure-Driven Processes

- Degrees of Membrane Separation

- Flux Behavior in Membrane Processes

Module Configurations & Processes

-> View all membrane resourcesTUTORIALS