NFS™ Seawater Sulfate Removal Case Study

Download Full Case Study

Overview

The objective of this study was to examine the performance of Synder’s NFS sulfate removal membrane against that of a leading competitor with an incoming feed stream representative of that found in the field. ASTM D1141-52 is a well-known, standard practice for the preparation of substitute ocean water and was therefore used in this study to simulate seawater, a common feed for waterflood injection processes.

Experimental

Synder’s NFS and a sulfate removal membrane from a leading competitor were tested in 2540 spiral wound element modules. ASTM D1141-52 synthetic seasalt was used as the incoming feed. Elements were tested at 330 psi with a feed flow rate of 3 gpm at 25°C. Permeate flux and sulfate rejection were recorded at 0%, 25%, 50%, and 75% total system recovery. Sulfate rejection was determined using Hach SulfaVer 4 Sulfate Reagent in conjunction with a Hach 1720E Series 2 spectrophotometer.

Project Goal

Examine performance of Synder’s NFS sulfate removal membrane with synthetic seawater

Feed

ASTM D1141-52 Synthetic Seasalt

Elements

2540 Synder NFS

2540 Competitor Element

Parameters Measured

Permeate flux

Sulfate rejection

Testing Conditions

Pressure: 330psi

Feed flow rate: 3gpm

Temperature: 25°C

Table 1: ASTM D1141-52 Synthetic Seawater Composition

| Sea Salt Mix | Conc. (g/L) | % of Sea Salt Mix |

| NaCl | 24.53 | 58.49 |

| MgCl2 | 5.20 | 26.46 |

| Na2SO4 | 4.09 | 9.75 |

| CaCl2 | 1.16 | 2.765 |

| KCl | 0.695 | 1.645 |

| NaHCO3 | 0.201 | 0.477 |

| KBr | 0.101 | 0.238 |

| H3BO3 | 0.027 | 0.071 |

| SrCl2 | 0.025 | 0.095 |

| NaF | 0.003 | 0.007 |

| TOTAL | 36.032 | 100.0 |

Results

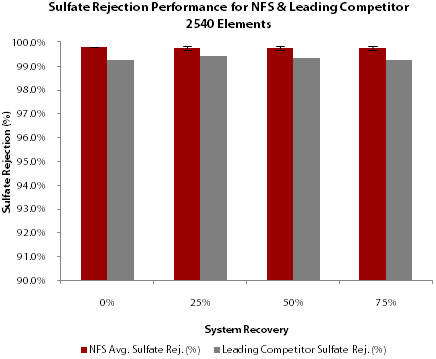

Figure 1: Average sulfate rejection performance for NFS and the leading competitor 2540 elements.

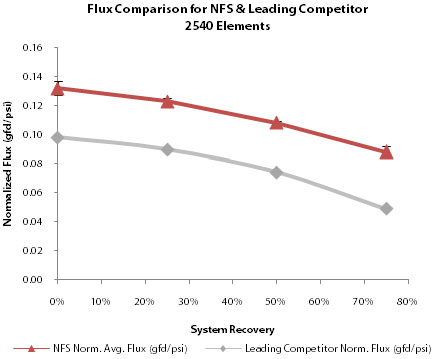

Figure 2: Average normalized flux (gfd/psi) performance for NFS and the leading competitor 2540 elements. Data was collected from 0 to 75% recovery.

Conclusion

The results of this study indicate that NFS demonstrates superior sulfate rejection and flux performance versus a leading competitor in a feed stream comprised of ASTM D1141-52 synthetic seasalt. Throughout the duration of the study, NFS had an average sulfate rejection of greater than 99.5% compared to 99.2% rejection observed for the leading competitor. More noticeable was the increased flux observed for NFS, which was approximately 25-30% greater overall, and lower flux decay which was ~33% for NFS and ~50% for the leading competitor. These results indicate that Synder’s NFS membrane is suitable for EOR techniques and sulfate removal applications throughout the oil and gas industry.

Contact Us

4941 Allison Parkway

Vacaville, CA 95688, USA

Phone: 1 (707) 451-6060

Fax: 1 (707) 451-6064

Email: sales@synderfiltration.com

questions? Fill out this form. We’ll contact you within 24 hours!

CASE STUDY

SEAWATER SULFATE REMOVAL

As global demand rises, nanofiltration technology has become essential throughout the oil and gas industry by improving the efficiency of waterflooding… //READ MORE

Applications

Resources

MEMBRANE RESOURCES

- Definition of a Membrane

- Membrane Materials: Organic vs. Inorganic

- Pressure-Driven Membrane Filtration Processes

- Concentration Polarization in Pressure-Driven Processes

- Degrees of Membrane Separation

- Flux Behavior in Membrane Processes

Module Configurations & Processes

-> View all membrane resourcesTUTORIALS