Dye Concentration Process

Download Full Case StudyIntroduction

The goal of the study is to determine if Synder’s NFX membraneis capable of handling five different dye products (different MW, strength/concentration, salt content) with minimum product loss during the desalination and concentration process.

Membrane and operating conditions

| Dye Conditions | |

| Dye MWCO | Varied, 500-1000 Da |

| NaCl concentration | Varied, 0.1% – 6.6% |

| Concentration/rejection determination | Spectrophotometer with specified wavelength |

| Membrane | |

| Element | NFX-2-1812 |

| Spacer Size (mil) | 31 |

| Surface Area (sq. ft) | 28 |

| Operating Parameters | |

| Pressure (psi) | 110 psi |

| Crossflow (gpm) | 1.5 gpm |

| Dye Conditions | |||||

| Dye Color | Yellow #1 | Red | Yellow #2 | Blue #1 | Blue #2 |

| MW | 700-800 | 500-600 | 900-1000 | N/A | N/A |

| Strength | 31 | 30 | 71 | 55 | N/A |

| NaCl concentration in the dye | 0.07% | 0.17% | 6.6% | 1.5% | 0.26% |

| pH | 10 | 9 | 10 | 10 | 8 |

Results

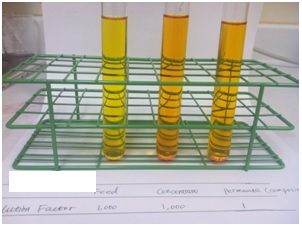

a) Yellow #1 dye – concentration process

The process goal is to remove 75% water. Synder NFX membrane has shown effective rejection of the yellow dye (Fig. 1). The absorbance measurement at 420 nm indicates 99.9% of the color dye was rejected by the membrane during the concentration process. The concentration process of yellow RW dye was completed at concentration factor of 3.2X; customer’s process goal is achieveable. The total color loss is expected to be less than 0.3%, predicted by the experimental results of 99.9% color rejection.

Fig. 1: Visual comparison for yellow RW dye: (from left to right: Feed with dilution factor of 1,000; concentrate with dilution factor of 1,000 and permeate with no dilution).

Fig. 1: Visual comparison for yellow RW dye: (from left to right: Feed with dilution factor of 1,000; concentrate with dilution factor of 1,000 and permeate with no dilution).B) Red dye – Diafiltration + concentration process

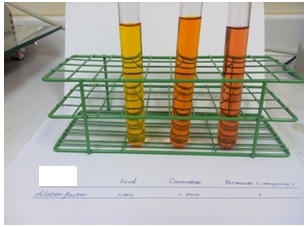

The process goal is to remove 75% water and 85% NaCl from the Red dye. With NFX membrane and continuous diafiltration, part of the salt was removed (salt concentration measured with conductivity). After diafiltration, the dye sample was concentrated by 4 fold, which equates to 75% water removal. The 99.9% color rejection, determined by the absorbance measurement at wavelength of 510 nm, is maintained during both diafiltration and concentration processes. At the end of diafiltration, 28 L of DI water was used to remove the salt from the 8 L of dye sample. The concentration process removed 6 L of samples from the feed. The total loss of color to the permeate is less than 0.5%. Depending on what was found from the NaCl concentration measurement, further diafiltration may be necessary. Synder do offer different NF membranes that have higher salt removal efficiency, however, it is likely the dye yield will change as salt removal efficiency increases.

Fig. 2: Visual comparison for red dye: (from left to right: Feed with dilution factor of 1,000; concentrate with dilution factor of 1,000 and permeate with no dilution).

Fig. 2: Visual comparison for red dye: (from left to right: Feed with dilution factor of 1,000; concentrate with dilution factor of 1,000 and permeate with no dilution).C) Yellow #2 dye – Diafiltration + concentration process

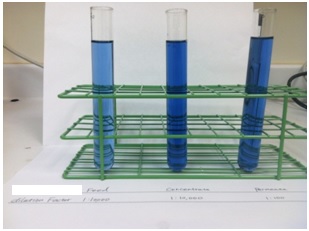

The process goal is to remove 35% of water and lower the NaCl concentration from feed solution. During continuous diafiltration, DI water equal to twice the feed volume was used to remote the salt content. Then the dye sample was concentrated to remove water from the feed solution. The 99.9% color rejection is maintained during both diafiltration and concentration processes, determined by the absorbance measurement at wavelength of 440 nm. The total loss of color to the permeate is less than 0.1%.

Fig. 3: Visual comparison for yellow dye: (from left to right: Feed with dilution factor of 1,000; concentrate with dilution factor of 1,000 and composite permeate with no dilution).

Fig. 3: Visual comparison for yellow dye: (from left to right: Feed with dilution factor of 1,000; concentrate with dilution factor of 1,000 and composite permeate with no dilution).D) Blue dye – Diafiltration + concentration process

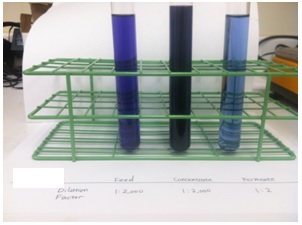

The process goal is to remove 70% of water and lower the NaCl concentration from the feed solution. A continuous diafiltration followed with a concentration process was applied. The overall color rejection was above 99%. The dye concentration was evaluated with the absorbance measurement at wavelength of 610 nm. The total loss of color to the permeate is less than 1%.

Fig. 4: Visual comparison for the Blue dye: (from left to right: Feed with dilution factor of 10,000; concentrate with dilution factor of 10,000 and composite permeate with dilution factor of 100).

Fig. 4: Visual comparison for the Blue dye: (from left to right: Feed with dilution factor of 10,000; concentrate with dilution factor of 10,000 and composite permeate with dilution factor of 100).E) Blue dye – concentration process

The process goal is to remove 60% of water and lower the NaCl concentration in the concentrate product. The absorbance of the dye samples was measurement at 600 nm. The readings indicate 99.9% of the color was rejected by the membrane during the entire concentration process. The total loss of color to the permeate is less than 0.2%.

Fig.5: Visual comparison for the Blue dye: (from left to right: Feed with dilution factor of 2,000; concentrate with dilution factor of 2,000 and composite permeate with dilution factor of 2).

Fig.5: Visual comparison for the Blue dye: (from left to right: Feed with dilution factor of 2,000; concentrate with dilution factor of 2,000 and composite permeate with dilution factor of 2). Suggestions and conclusions

The Synder NFX Membrane showed promising results on all five different dyes with minimum of 99% dye rejection. It provides an economical solution to the customer so that they can use the same membrane to process all their products in the plant.

questions? Fill out this form. We’ll contact you within 24 hours!

CASE STUDY

SEAWATER SULFATE REMOVAL

As global demand rises, nanofiltration technology has become essential throughout the oil and gas industry by improving the efficiency of waterflooding… //READ MORE

Applications

Resources

MEMBRANE RESOURCES

- Definition of a Membrane

- Membrane Materials: Organic vs. Inorganic

- Pressure-Driven Membrane Filtration Processes

- Concentration Polarization in Pressure-Driven Processes

- Degrees of Membrane Separation

- Flux Behavior in Membrane Processes

Module Configurations & Processes

-> View all membrane resourcesTUTORIALS