Open Channel Ribbed Spacer for High Solids Applications

Download Full Case Study

Background

Feed spacer geometry can be just as crucial as spacer thickness in high solids applications, such as whey protein concentration. The objective of this study was to examine differences in flux and pressure drop performance between Synder’s ST (PES 10kDa) elements with standard 80mil diamond and open channel ribbed spacers in order to identify any potential advantages of switching to an open channel ribbed spacer.

Feed Solution, Membrane, and Operating Conditions

| Table 1: Feed composition and operating parameters | |

| Feed Solution | |

| Material | Kraft Foods Global, Sweet Whey |

| Sweet Whey Concentration | 20wt% |

| Synder Membrane | |

| Elements | ST-5B-2540M (Standard Diamond) |

| Operating Parameters | |

| Pressure (PSI) | 120 |

| Crossflow Rate (GPM) | 4 |

| Temperature (C) | 25 |

Results

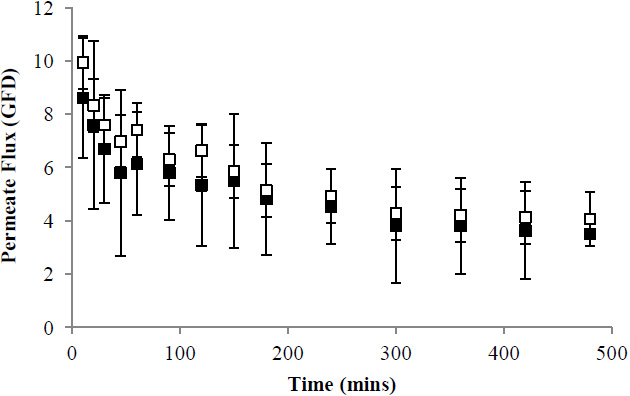

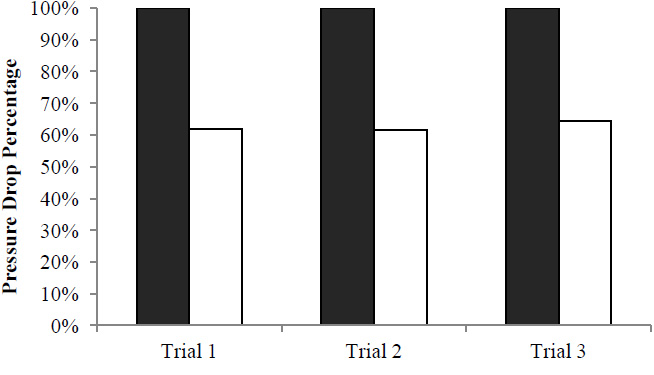

Examination of permeate flux trends from three independent trials using a total of 6 elements indicated no significant difference in flux performance between elements containing either of the two spacer types (Figure 1). High protein rejection for all tested elements indicates that the obtained flux values are unlikely to have arisen as a result of a loss of membrane integrity. Despite little difference in flux performance, a more noticeable difference was observed with respect to element pressure differential, where elements containing open channel ribbed spacers showed reduce pressure drop (Table 2). The use of a ribbed spacer showed a reduction in pressure drop of at least 37% across the length of the element (Table 3). The expected pressure drop values for elements with larger diameters were subsequently extrapolated according to open flow channel area and assuming no change in operating conditions (Table 4).

Figure 1. Permeate flux values of ST elements containing diamond net (■) and open channel ribbed spacers (□). Error bars represent standard deviation of n=3 samples.

Figure 1. Permeate flux values of ST elements containing diamond net (■) and open channel ribbed spacers (□). Error bars represent standard deviation of n=3 samples.

| Table 2: Average recorded ΔP and protein rejection values for each run. | ||||||||

| Element Model | Spacer Type |

|

||||||

| ST-5B-2540M | 80mil Diamond |

|

||||||

| ST-5PB-2540M | 80mil Ribbed |

|

||||||

Figure 2. Pressure drop of ST elements containing diamond net (■) and

open channel ribbed spacers (□) expressed as a percent of diamond net

pressure drop.

Figure 2. Pressure drop of ST elements containing diamond net (■) and

open channel ribbed spacers (□) expressed as a percent of diamond net

pressure drop.

| Table 3. Calculated pressure drop reductions between 2540 elements with diamond and open channel ribbed spacers. | |||||||

| Spacer Type |

|

||||||

| 80mil Diamond |

|

||||||

| 80mil Ribbed |

|

||||||

| Pressure Drop Reduction |

|

||||||

| Average Pressure Drop Reduction | 37% | ||||||

Conclusion

The data obtained in this study indicates that the use of open channel ribbed spacers may offer distinct advantages over standard diamond spacers in high solid applications such as whey protein concentration. Despite no observable differences in flux performance when challenged with 20% total solids in the form of sweet whey, there was a significant difference between the two configurations with respect to pressure drop, where ribbed spacers showed a calculated pressure drop reduction of 37% compared to diamond net. When extrapolated for larger elements, the differences in pressure drop become increasingly more apparent, with a predicted difference of nearly 20psi for a 10” element under the same conditions. These results suggest that open channel ribbed spacers have the potential to increase element run time between CIPs through a reduction in pressure drop, which can subsequently result in decreased energy consumption and reduced operating costs.

questions? Fill out this form. We’ll contact you within 24 hours!

CASE STUDY

SEAWATER SULFATE REMOVAL

As global demand rises, nanofiltration technology has become essential throughout the oil and gas industry by improving the efficiency of waterflooding… //READ MORE

Applications

Resources

MEMBRANE RESOURCES

- Definition of a Membrane

- Membrane Materials: Organic vs. Inorganic

- Pressure-Driven Membrane Filtration Processes

- Concentration Polarization in Pressure-Driven Processes

- Degrees of Membrane Separation

- Flux Behavior in Membrane Processes

Module Configurations & Processes

-> View all membrane resourcesTUTORIALS