Membrane Technology

Selective Transport

Synder Filtration’s polymeric membranes are used to separate, concentrate, or fractionate a wide variety of liquids. Membranes serve as a thin barrier between miscible fluids that allow for preferential transport of one or more feed components when a driving force is applied, such as a pressure differential.

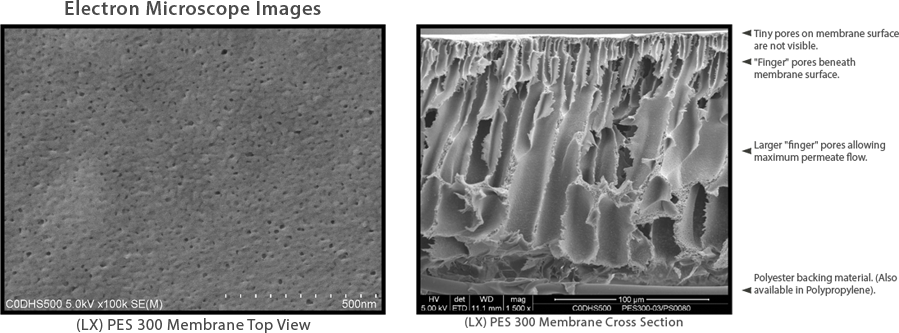

Asymmetric Pore Structure

Synder membranes feature an asymmetric pore structure. Small surface pores control rejection of target molecules while large “finger pores” beneath the membrane surface allow permeate to move quickly through to a more open permeate carrier. This combination, along with membrane thickness, offers an optimal combination of selectivity and permeate flux.

Tangential Flow Process

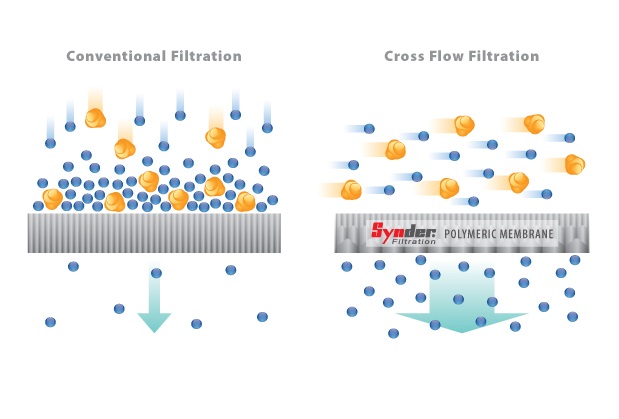

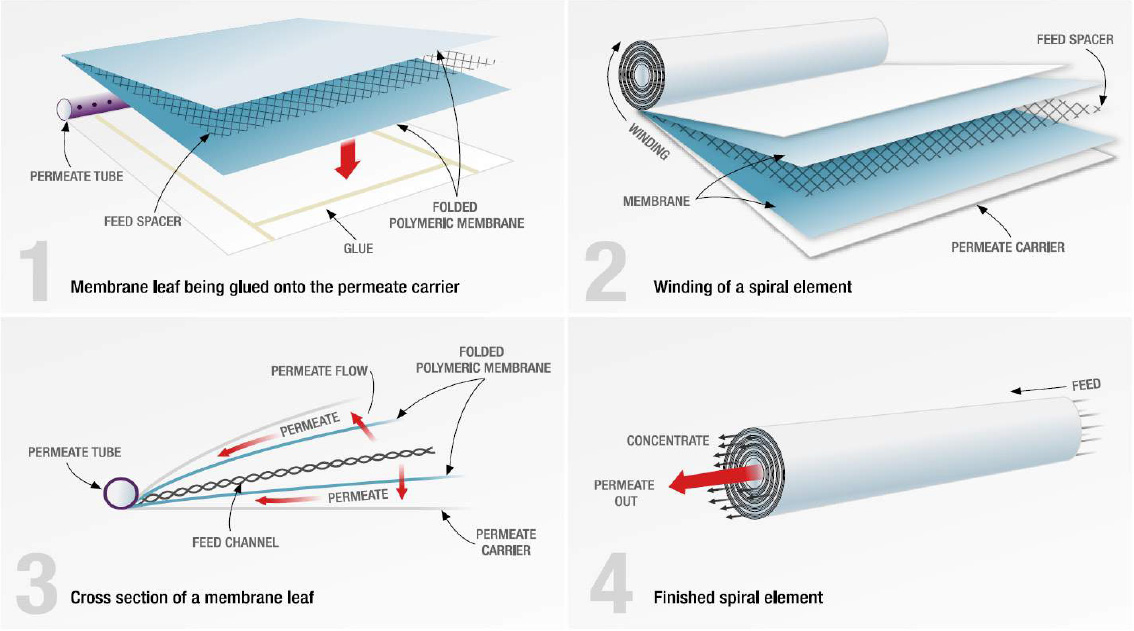

Spiral wound membrane elements are fed tangentially. When sufficient pressure or concentration differentials exist on the surface of the membrane, molecules smaller than the surface pores will be driven through it. This solution that passes through the membrane is called the permeate, while the solution rejected by the membrane is called the concentrate (or retentate).

Molecular Weight Cut-Off and Membrane Selection

Depending on polymer types and preparation methods, most of the polymeric membranes have a wide bell-shape pore size distribution. The concept of Molecular Weight Cut-Off (MWCO) is used as a common way to characterize the pore size distribution for porous membranes, typically for ultrafiltration and microfiltration membranes. MWCO is defined as that molecular weight which is 90% rejected by the membrane [1] and such value can only be used as a reference due to the facts that large pore size distribution is intrinsic to polymeric membrane and that different membrane manufacturers have their own standard of measurements. Furthermore, retention is governed not only by size and shape of the solutes, but also by the electrostatic interaction and steric hindrance as well as solute membrane affinity such as hydrogen bonding. It can also be influenced by solution chemistry and ionic strength. Therefore, membrane filtration is a trial-and error process and pilot studies are recommended to select the best membrane for a specific application.

At Synder, Dextran (a branched, neutral charged polysaccharide) of various molecular weights is used to rate the MWCO of our membranes. The unit of molecular weight (or, more correctly, mass) is Dalton [2]. From the same supplier, the membrane with higher MWCO is always more porous than the ones with lower MWCO, but these numbers should be used with caution when comparing between membranes made by different vendors as each might utilize its own qualification method. Synder is proud to have the widest MWCO selection of membranes for process optimization.

[1] Marcel Mulder, “Basic Principles of Membrane Technology”, 2nd ed., Kluwer Academic Publishers, 2000.

[2] Ken Sutherland, “A – Z of Filtration and Related Separations”, 1st ed., Elsevier, 2005.

Conventional vs. Tangential Flow

Synder’s spiral wound membranes are designed for tangential flow (or cross flow) filtration, where the feed stream runs parallel to the membrane surface. Unlike conventional filtration where solids and solutes immediately accumulate on the membrane surface, tangential flow creates a sweeping (or shearing) force along the surface of the membrane to provide for longer filter life and less frequent cleaning cycles under normal operating conditions.

Spiral Wound Element: A Dissection

Application Development Program

Learn more about Synder’s comprehensive custom application development program and wide variety of pilot systems available for testing. Here at Synder, we realize the importance of flexibility and responsiveness, which is why we created a comprehensive application development program to fulfill specific separation needs. We work closely with our customers to fully understand, design, and deliver both custom membranes and systems.

questions? Fill out this form. We’ll contact you within 24 hours!

At Synder Filtration, we take pride in providing technical expertise and personal collaboration with our customers. With our newly designed research & development laboratory and fleet of pilot systems, we are able to conduct a wide range of feasibility tests both in-house and on-site. … [read more]

Membrane Development Program

At Synder Filtration, we aim to provide quality products, technical expertise, and quick responsiveness. With our state-of-the-art laboratory, extensive array of pilot systems, and growing team of scientists and engineers, we are able to develop and customize innovative membranes to fit specific process separation needs and applications across all industries. We take pride in collaborating closely with our customers to ensure consistent… [read more]