Custom Membrane Systems

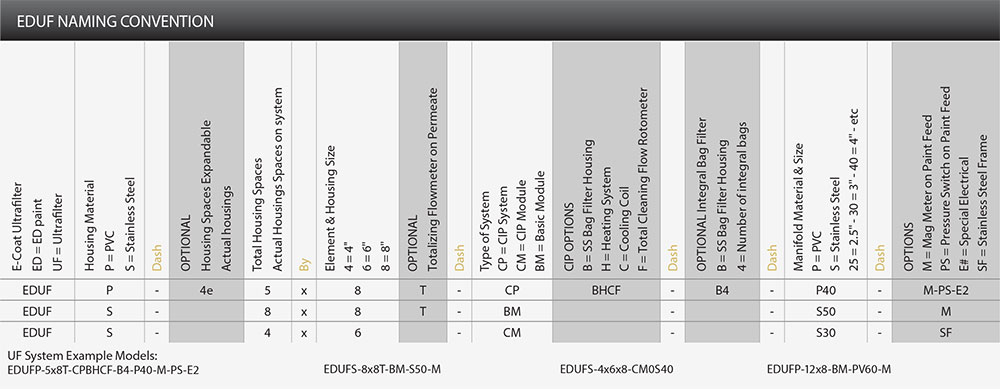

EDUF Systems

Synder Filtration offers a complete suite of membrane products for the ECoat industry. Aside from our specially designed V-series elements which are well suited for any cathodic paint bath, we offer custom built Electrodeposition Ultra Filtration systems (EDUF) which guarantee optimal performance for your paint process. This premium quality product is achieved through a collaborative effort between our engineers and customers. Synder is proud to have a majority of automotive system installations in North America.

uf system operating specifications

Operational Parameters and Limitations for Electrodeposition Systems

| Maximum operating pressure at element inlet | 60 PSIG |

| Maximum operating pressure at element outlet | 40 PSIG |

| Minimum operating pressure at element outlet | 5 PSIG |

| Minimum pressure drop per element at 70 GPM/element | 20 PSIG |

| Design pressure drop per element at 70 GPM/element | 25 PSIG |

| Maximum pressure drop per element at 70 GPM/element | 35 PSIG |

| Minimum feed rate per V62-7647.5 inch element | 65 GPM |

| Design feed rate per V62-7647.5 inch element | 70 GPM |

Maximum operating temperature/cleaning

| (Schedule 80 PVC piped EDUF System) | 120° F @ 50 PSI |

| (Stainless Steel / CPVC piped EDUF System) | 140° F @ 110 PSI |

Maximum operating temperature/paint – per paint manufacturer’s specifications

| Maximum pressure at permeate outlet | 5 PSIG |

| Recommended cleaning pressure profiles | 25 – 30 psi inlet pressure |

| (Note: all valves 100% open) | 0 – 5 psi outlet pressure |

| pH range/cleaning | 2.0 – 12.0 @ 110° F |

| 4.5 – 11.0 @ 120° F |

- Housing Vessel

- Housing Flow Meters

- Stainless Steel Ball valves

- Butterfly Valves

- PVC Ball Valves

- Gauges/Isolator

standard module system parts

- CIP Pump

- One/Two Point Temperature Switch

- Cooling Coil

- CIP Tank Heater

- CIP Flow Meter

standard cip system parts

uf systems features and benefits

- Integral bag filters reduce costs and save floor space

- CIP system: Clean a single element while rest of system remains online.

- Available bag filter in CIP loop.

- Stainless Steel housings.

- Stainless Steel top & Bottom caps are standard.

- After Sales Support: We’ll be there to monitor and optimize system performance.

Resources

MEMBRANE RESOURCES

- Definition of a Membrane

- Membrane Materials: Organic vs. Inorganic

- Pressure-Driven Membrane Filtration Processes

- Concentration Polarization in Pressure-Driven Processes

- Degrees of Membrane Separation

- Flux Behavior in Membrane Processes

Module Configurations & Processes

-> View all membrane resourcesTUTORIALS