Custom Membrane Systems

Sanitary Systems

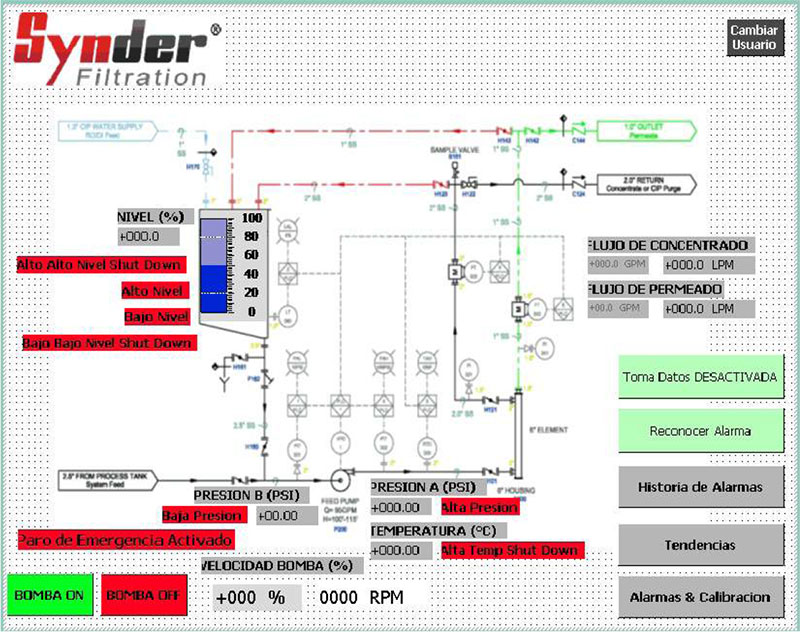

Synder provides custom sanitary systems, and industrial systems with sanitary weld & component requirements. Many of the components are easily removeable and disassembled for cleaning, and have low interior surface roughness. From pilot units to production scale units, Synder’s Engineering team will work closely with the customer from design to manufacturing to ensure the system meets all specifications.

standard sanitary features

- Housing vessel

- Stainless steel valves

- Pressure gauges

- Pump

- Temperature sensor

- Flow sensor

- Custom tank with level sensor

sanitary system benefits

Sanitary compenents are easily removal and can be disassembled for cleaning. Fine surface roughness and sanitary designs also prevent build-up and potential contamination.

options and customization

- Feed and booster pumps

- Feed and product storage tanks

- Custom system design and configuration

- Automation and controls customization

- Various PLC and controllers

- Custom PLC program and alarm features

- Custom touch screen HMI interfaces

- Data logging

- Remote monitoring

- Wide selection of sensors and instrumentations to best suit the customers needs

- Synder’s Engineering team will work with the customer to allow our systems to be integrated into their facility seamlessly

Resources

MEMBRANE RESOURCES

- Definition of a Membrane

- Membrane Materials: Organic vs. Inorganic

- Pressure-Driven Membrane Filtration Processes

- Concentration Polarization in Pressure-Driven Processes

- Degrees of Membrane Separation

- Flux Behavior in Membrane Processes

Module Configurations & Processes

-> View all membrane resourcesTUTORIALS