![]() Super CELLTM

Super CELLTM

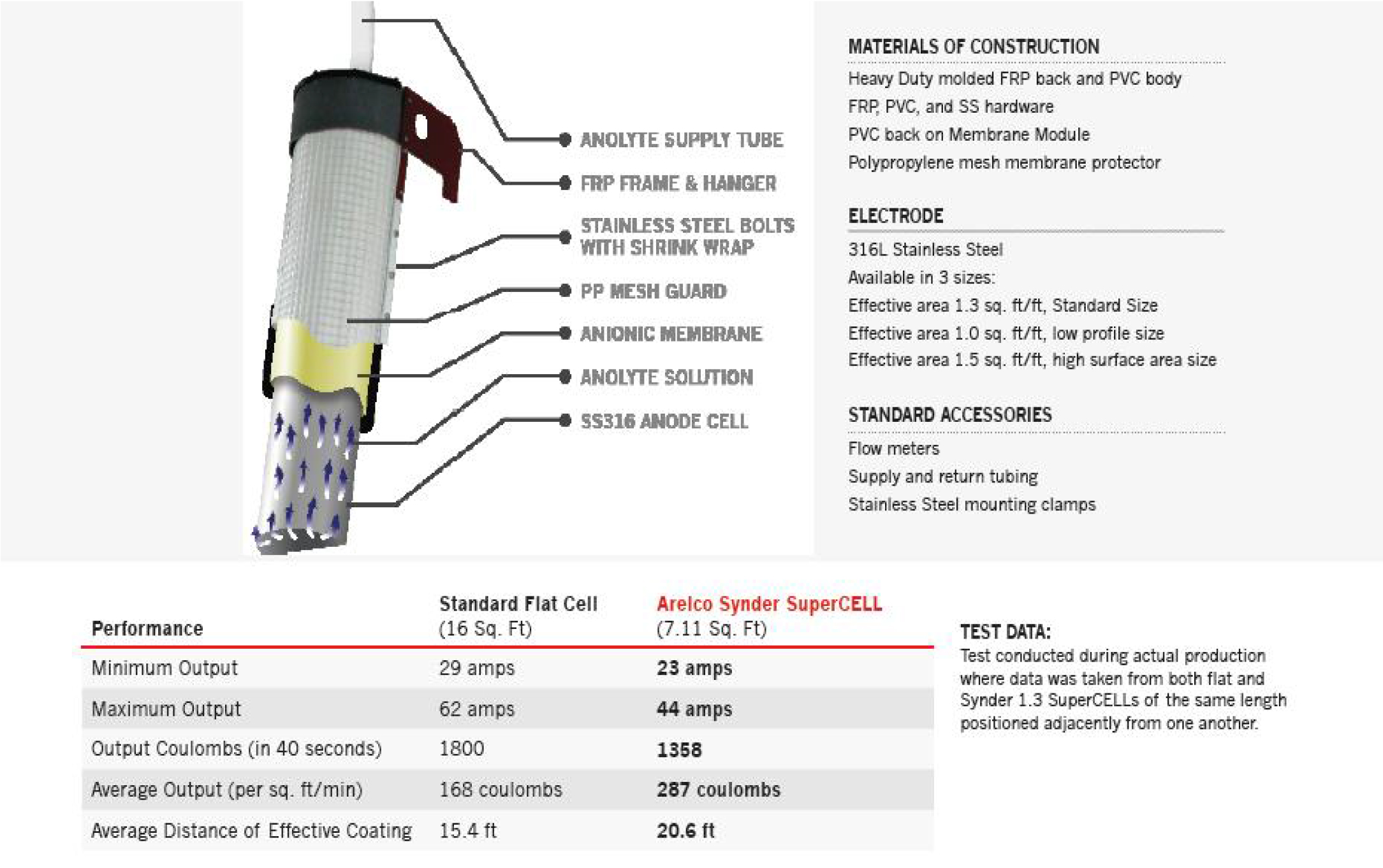

Synder Filtration’s SuperCELLTM is a heavy duty, lightweight, one piece C-Cell anode cell designed for optimum paint coverage in large electrocoat paint tanks. It offers incredible efficiency and performance with 100% of the cell facing the job and is thus the most economic option for large volume paint tanks.

FEATURES AND BENEFITS

Lower Operating CostsIncreased amps per square foot and subsequent savings in electrical power usage provide for dramatic reductions in operating costs vs. box cells

Better CoverageMore throw angles mean greater coverage and longer paint times in monorail systems

Easy to Use & MaintainHeavy duty, light weight, and in one piece to ensure easy lifting and simple power cable connections.

Flexibility For Your TankAvailable in four different sizes, including a low profile option for tanks with limited clearance between the part and tank wall.

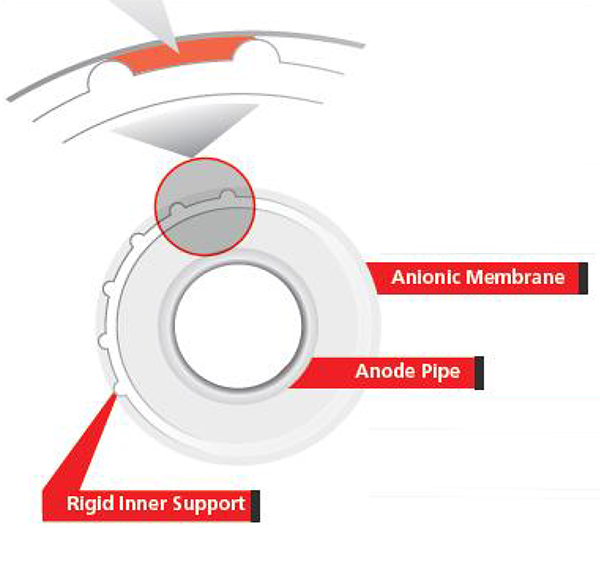

Annular space between membrane and inner support greatly improves rinsing of membrane to reduce foulants, such as iron oxide. This in turn minimizes build up of electrical resistance on the membrane.

ANODE CELL EXAMPLE

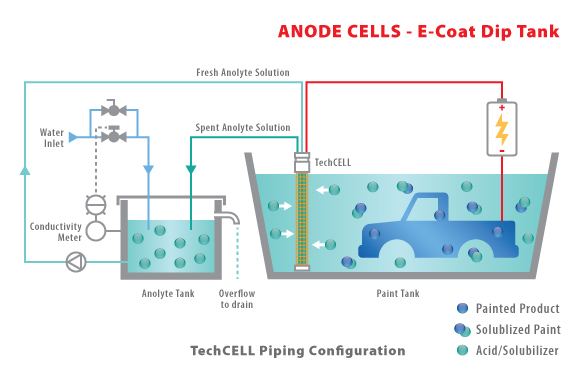

ANOLYTE RECIRCULATION SYSTEM

Synder Filtration’s Anolyte Recirculation System offers advanced conductivity controllers, ultrasonic level sensors, and UV systems to meet the needs of both automotive and industrial E-Coat applications. These can be customized to fit your specific requirements

SUPER CELL DESIGN

- Semicircular anode & membrane

- Designed for ease in lifting and connecting to the power cable

- Weighs less than 1/3 of a standard flat cell

- No welds below the anolyte fluid to prevent failure due to submerged mechanical or welded connections

- Made from 10 gauge or 3/16” thick 316L stainless steel

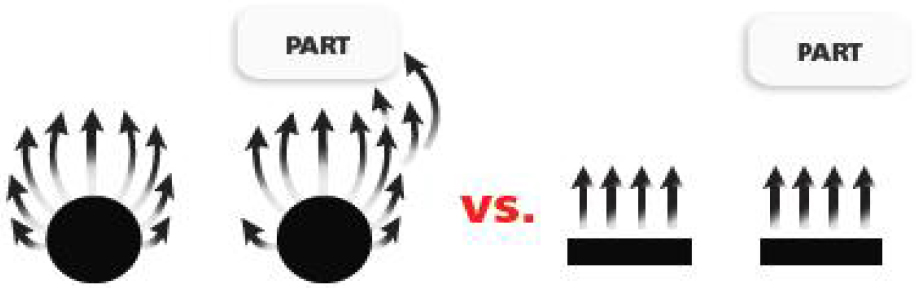

BETTER THROW ANGLES

The Super CELLTM offers a greater range of electrical “throw angles” vs. flat cells. A greater variety of throw angles can significantly improve the coating quality and coverage in hard to reach areas of the part.

More throw angles also allow the anode to start painting sooner in monorail systems.

Applications

questions? Fill out this form. We’ll contact you within 24 hours!

Resources

MEMBRANE RESOURCES

- Definition of a Membrane

- Membrane Materials: Organic vs. Inorganic

- Pressure-Driven Membrane Filtration Processes

- Concentration Polarization in Pressure-Driven Processes

- Degrees of Membrane Separation

- Flux Behavior in Membrane Processes

Module Configurations & Processes

-> View all membrane resourcesTUTORIALS