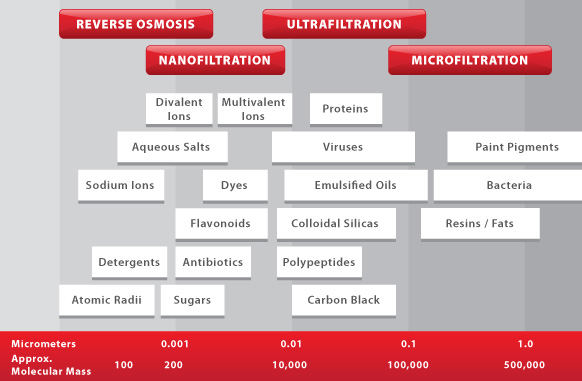

Degrees of Membrane Separation

Microfiltration

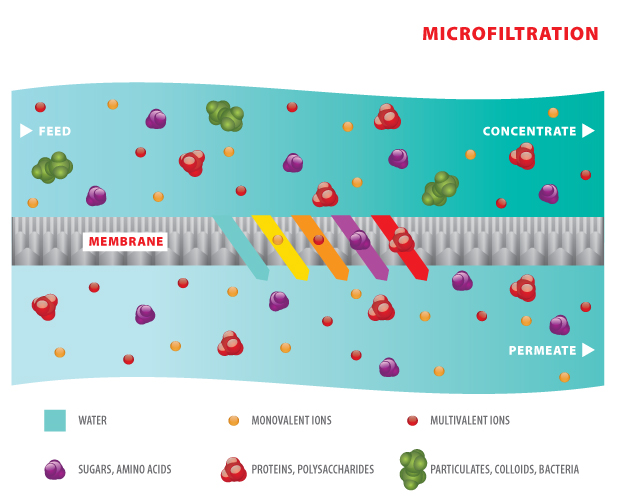

Microfiltration (MF) membranes feature the largest pore sizes of Synder’s membrane product line, ranging from 800kDa to 0.2µ. MF membranes provide a high degree of permeation for water, salts, sugars, amino acids, proteins, and polysaccharides.

Synder’s microfiltration membranes are commonly used as pretreatment or clarification step to ultrafiltration and nanofiltration processes, but can also be used to fractionate large macromolecules from smaller ones, such as casein/ whey fractionation in the dairy industry. In the biotech and pharmaceutical industries, MF membranes offer the safety of a physical barrier to remove bacteria and other microbes.

Synder offers both spiral wound and flat sheet membrane configurations in a variety of dimensions.

Microfiltration Applications

- Fat/Microbial Removal and Casein/Whey Fractionation

- Gelatin and Wine Clarification

- Corn Wet Milling

- Plant Extract Clarification

- Industrial Process Wastewater Treatment

- Clarification of Fermentation Broths

- Beverage Sterilization

Synder Microfiltration Membrane Characteristics

- Constructed with a robust PVDF Polymer, these membranes are thermally and chemically resistant and have a high tolerance for hydrocarbons and oxidizing environments compared to membranes with PES polymer

- Proprietary hydrophilic charge available to keep the membrane cleaner overtime

- No additional chemicals needed to recharge the membrane overtime

- Synder’s MF MAX series is ideal for applications with extreme pH or temperature ranges

- Extends life of NF/RO elements when used as pretreatment

- Turbidity & TSS removal in feed solutions with 2-3% concentration of large solid sizes

Ultrafiltration

Synder offers an extensive and growing range of spiral-wound Ultrafiltration (UF) membrane Molecular Weight Cut-Offs.

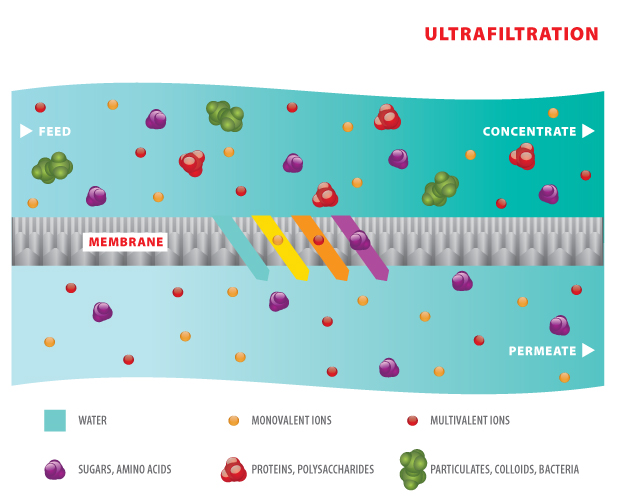

Synder Filtration’s extensive line of polymeric Ultrafiltration membranes have a molecular weight cutoff (MWCO) ranging from 1kD-500kD. UF membranes are used predominantly for the concentration of macromolecules, especially proteins. In comparison with microfiltration, ultrafiltration membranes are notably used to reject viruses, in addition to macromolecules and proteins. Synder manufactures both flat sheet and spiral-wound membranes, and can develop customized UF membranes as needed with great speed and flexibility.

Common Applications

- Whey Protein Concentrate/Isolate Production

- Enzyme/Protein Concentration

- Endotoxin and Pyrogen Removal

- Electrocoat Paint: CathodicElectrocoat Paint Recovery

- Process Wastewater Treatment

Synder Ultrafiltration Membrane Characteristics

- Flexibility with a wide range of both PES & PVDF UF membranes

- High resistance to fouling

- Customizable membranes through a wide range of materials

- MAX series membranes are ideal for applications with more extreme pH or temperature ranges

Nanofiltration

Synder’s Nanofiltration (NF) membranes: Better Rejection, Greater Flux.

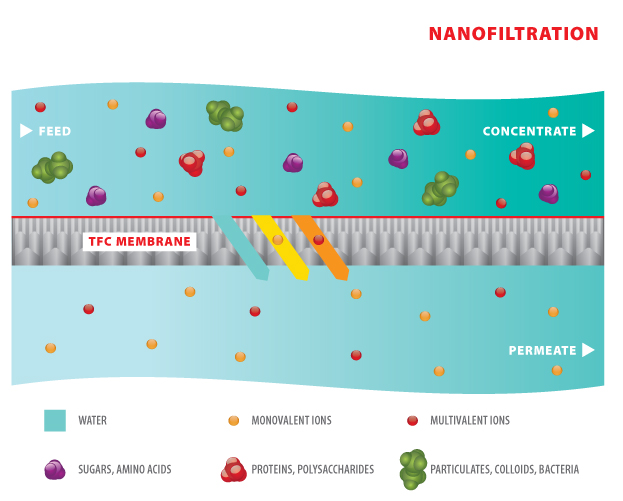

The NFX, NFW, & NFG membranes encompass molecular weight cutoffs (MWCO) from 150-800Da and have typically displayed better rejection and greater flux than the leading competitor. With high rejections of hardness, metals, and organic matter, and lower operating pressures than reverse osmosis membranes (0.3-4.0MPa), Synder’s NF membranes and systems are the economical option in certain water treatment applications. Contact us (create link to email inquiry) today to find a solution for you.

Common Applications

- Hardness, Heavy Metal, Nitrate, Sulfate, Tannin, Odor, Color, and TDS Removal

- Lactose Concentration

- Dealcoholization, Fragrance Recovery, Maple Syrup Concentration

- Antibiotics Production

- Polyvinyl Alcohol Recovery

- Precious Metal Recovery

- Coal Bed Methane Processing

Features & Benefits of Synder’s NF Membranes

- Flexibility with two models – the NFX & NFW

- Better Rejection with a minimum 98% and 99.3% MgSO4 rejection by the NFW and NFX membranes, respectively

- 30-50% Greater Flux than the leading competitor

- Operate at lower pressure compared to RO membranes while still maintaining excellent rejection

- Significantly reduce levels of hardness, TDS, sulfates, turbidity, etc. from feed water streams

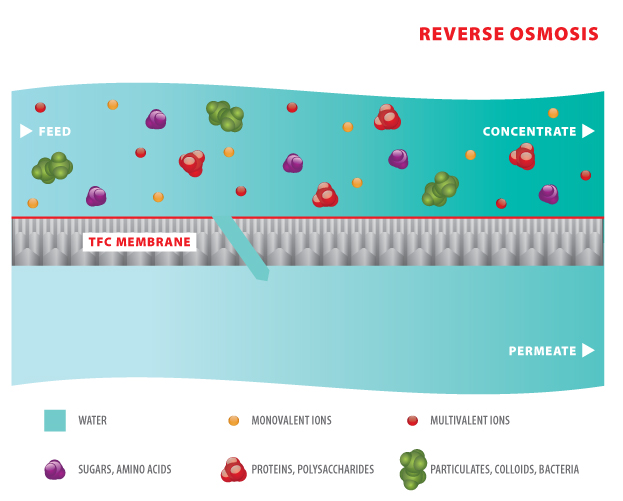

Reverse Osmosis

Ultrapure Water Production

Synder’s Reverse Osmosis (RO) membranes and systems can produce large volumes of ultrapure water with incredible efficiency. As illustrated below, through the application of pressure to concentrated solutions, water molecules can be driven through a membrane against natural osmotic pressure. This membrane separates these water molecules from all dissolved solids and other contaminants, thus producing ultrapure water. Salt retention values typically found when using RO membranes are between 98-99.9%. In terms of time and energy efficiency compared to other conventional processes, Synder’s RO technology is the ideal choice when economical ultrapure water treatment is a necessityAs pretreatment is typically a necessity for optimal RO performance, Synder can provide UF and NF membranes and systems to prevent fouling and protect the RO membranes.

Features & Benefits of Synder’s RO Systems

- Low operating costs& environmental impact compared to other commercial water purification systems

- High energy savings vs. conventional RO systems

- Portable cleaning methods

CASE STUDY

Applications

Resources

MEMBRANE RESOURCES

- Definition of a Membrane

- Membrane Materials: Organic vs. Inorganic

- Pressure-Driven Membrane Filtration Processes

- Concentration Polarization in Pressure-Driven Processes

- Degrees of Membrane Separation

- Flux Behavior in Membrane Processes

Module Configurations & Processes

-> View all membrane resourcesTUTORIALS