Characterization of Polymeric, Porous Membranes: UF/MF & Solute Rejection Measurements

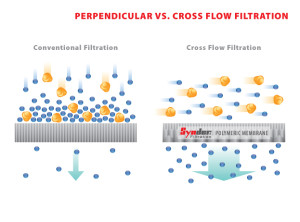

Microfiltration (MF) and ultrafiltration (UF) are processes that allow for the physical separation and retention of particles passing through the membrane. With a complex network of pores, small molecules are driven by forces such as pressure, concentration, and thermal gradients, while allowing for the retention of larger molecules within. The two most common methods that are applied to MF and UF are dead-end and cross-flow filtration. Dead-end filtration allows all of the feed solution to pass straight through, resulting in a layer of build-up on the surface of the membrane, while cross-flow filtrationcreates a pressure gradient as fluid flows tangentially across the membrane surface. The latter prevents solute build-up and reduces the overall amount of fouling and need for cleaning. Depending on the composition of the solution and degree of separation needed, MF and UF can also be used as pre-treatment options.With a pore size of approximately 0.1-10 μm and a molecular weight cut-off range of 0.2-0.08μ, microfiltration membranes are able to remove larger contaminants and even some viruses from a feed stream. In terms of solute rejection, MF is typically measured via gas permeation (i.e. using bubble points or gas-liquid porosimetry). With these larger pore sizes, MF is commonly used in applications such as beverage sterilization, wastewater treatment, and oil separation.

Ultrafiltration membranes have a slightly smaller pore size range of 0.001-0.1μm, and a molecular weight cut-off range of 1k-500k Da. Theypossessa higher overall retention rate when compared to MF membranes, which allows for further rejection of all viruses, macromolecules, and proteins. Regarding solute rejection, UF can be measured by passing molecules with a known molecular weight through the membrane (i.e. using markers such as polyethylene glycol or dextran). This type of filtration is most applicable for separation in the food and dairy industries, biotech, pharmaceutical, as well as in the automotive industry for cathodic paint recovery.

CASE STUDY

Applications

Resources

MEMBRANE RESOURCES

- Definition of a Membrane

- Membrane Materials: Organic vs. Inorganic

- Pressure-Driven Membrane Filtration Processes

- Concentration Polarization in Pressure-Driven Processes

- Degrees of Membrane Separation

- Flux Behavior in Membrane Processes

Module Configurations & Processes

-> View all membrane resourcesTUTORIALS