What are Microfiltration Membranes?

Intro

Synder Filtration offers a wide selection of microfiltration (MF) membranes developed specifically to solve complex process challenges such as microbial removal, protein fractionation, and pretreatment to other membrane processes. Available in both spiral-wound and flat sheet configurations, microfiltration membranes and membrane systems can be customized to meet specific application goals with efficiency.

Overview

Microfiltration is a low pressure separation process utilizing membranes with very open pore structures. Microfiltration filters can be made with both organic materials, such as polymer based membranes, as well as inorganic materials, such as ceramic or stainless steel. In selecting the appropriate membrane, spiral-wound polymeric microfiltration filters are often the starting point for consideration, based on spiral MF’s balance of durability, membrane area per unit, and significantly lower membrane unit cost, and equipment capital cost vs. ceramic and stainless options.

MF Products

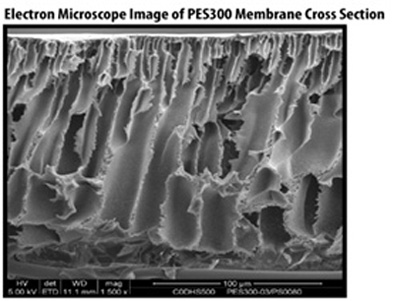

Microfiltration membranes have the most open pore sizes of all polymeric membranes. With a pore size range of 0.1 to 10μm, microfiltration membranes are capable of separating large suspended solids such as colloids, particulates, fat, and bacteria, while allowing sugars, proteins, salts, and low molecular weight molecules pass through the membrane. MF membranes feature an asymmetric pore structure, with tighter surface pores to control rejection, and more open macrovoids in the membrane cross section, in order to optimize flux.

Synder Filtration currently offers three types of polymeric microfiltration membrane filters, all of which maintain good resistance to pH, temperature, and fouling tendencies. They are also commonly used as a pretreatment step for feed stream applications. These PVDF microfiltration membrane filters are manufactured to sustain excellent chemical and heat resistance, and are available in both spiral-wound and flat sheet configurations, to provide more flexibility for customization around specific process applications.

Synder’s sanitary microfiltration membranes are also compliant with FDA standards listed in CFR Title 21, 3-A Sanitary Standards No. 45-02, as well as USDA sanitary standards and are fit for use in a variety of sanitary, as well as industrial applications across a broad spectrum of industries.

MF Applications

Microfiltration is a physical separation process that removes contaminants such as suspended solids, fats, and microbes from process fluids. Microfiltration may also be used in combination with other membrane technologies such as reverse osmosis, nanofiltration, and ultrafiltration. Common applications of Synder’s MF membrane technology include:

Dairy

- Fat / microbial removal in Whey Protein Concentrate / Isolate

- Casein / Whey fractionation

- Clarification of fermentation broths

- Microbial removal, clarification

Food/Beverage

- Plant extract clarification

- Gelatin clarification

- Wine clarification

- Corn wet milling

Industrial/Wastewater Treatment

- Industrial process wastewater treatment

Synder offers a comprehensive application development program as well as custom microfiltration membrane development in certain cases. Please refer to the applications and/or case studies page for more information about microfiltration membrane applications, or if you have specific questions, please feel free to contact us. You will receive a personal response from one of our experienced team members within 24 hours!

questions? Fill out this form. We’ll contact you within 24 hours!

CASE STUDY

Applications

Resources

MEMBRANE RESOURCES

- Definition of a Membrane

- Membrane Materials: Organic vs. Inorganic

- Pressure-Driven Membrane Filtration Processes

- Concentration Polarization in Pressure-Driven Processes

- Degrees of Membrane Separation

- Flux Behavior in Membrane Processes

Module Configurations & Processes

-> View all membrane resourcesTUTORIALS