Microfiltration Membrane Manufacturing

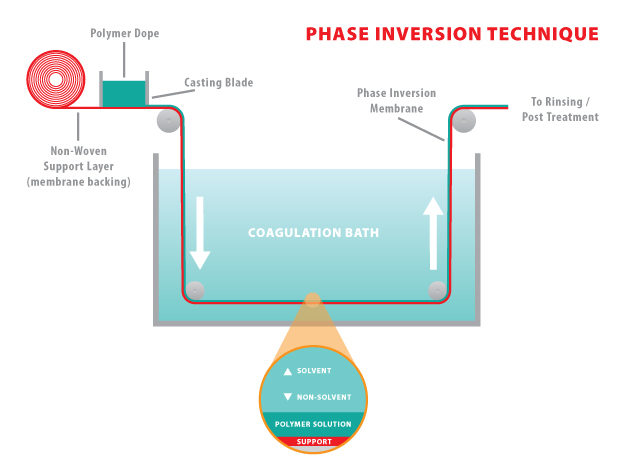

In the production of microfiltration membranes, a polymeric membrane is first cast onto a backing material made of uniform fibers. This is done through the use of a quenching process that solidifies the polymer dope into a physical membrane while drawing the solvents out. The membrane leaves, permeate tricot, and feed spacer are then rolled up together to form the MF element. Synder’s elements undergo extensive quality control guidelines to ensure the strict quality control standards are being met on a daily basis.

Synder Filtration is an ISO-9001:2015 certified microfiltration membrane manufacturer headquartered in Vacaville, California. As a microfiltration membrane supplier, Synder is capable of manufacturing MF membrane flat sheets, spiral wound MF elements, and designing and fabricating MF systems as well.

Synder Inc. was originally founded in 1989 with a focus on industrial enzyme processing. The founders pioneered the use of spiral membranes in the industrial biotech field, but eventually became unsatisfied with the product quality and lack of technical support from their existing membrane supplier. After a futile search for alternative suppliers, the founders established Synder Filtration in 1994 as a custom membrane manufacturer focused on specialty process applications.

As a former membrane customer ourselves, we know how important it is for a microfiltration membrane supplier to provide timely service, knowledgeable support, and fast lead times. As a financially independent family business, we are able to invest heavily in our inventory to ensure the fastest delivery times possible.

Please contact us to request more information. You will receive a personal response from one of our experienced team members within 24 hours!

questions? Fill out this form. We’ll contact you within 24 hours!

CASE STUDY

Applications

Resources

MEMBRANE RESOURCES

- Definition of a Membrane

- Membrane Materials: Organic vs. Inorganic

- Pressure-Driven Membrane Filtration Processes

- Concentration Polarization in Pressure-Driven Processes

- Degrees of Membrane Separation

- Flux Behavior in Membrane Processes

Module Configurations & Processes

-> View all membrane resourcesTUTORIALS