NF Whey Concentration & De-ashing Case Study

Download Full Case Study

Overview

The objective of this study was to examine the flux and calcium rejection performance of Synder’s NFX and NFS membranes, with acid whey powder used as the incoming feed stream. These results will determine the potential for NFS to be used in the dairy industry for applications such as whey concentration, decalcification, and de-ashing.

Experimental

Synder’s NFX and NFS membranes were tested in 2540 spiral wound element modules. Acid whey powder (8wt%) was used as the incoming feed. Elements were tested at 490 psi with a feed flow rate of 2 gpm at 25°C. Permeate flux and calcium rejection was measured from 1x to 3x volumetric concentration factor (VCF). Calcium concentration was determined using the USEPA buret titration method with Hach CalVer calcium indicators.

| Table 1: Acid Whey Powder Composition | |

| Description | Specification |

| Ash | 10.5% max |

| Fat | 1.2 max |

| Moisture | 5.0 max |

| pH | 4.5-5.0 |

| Protein (as is) | 11% min |

| Sediment | 15.0 mg max |

| Titratable Acidity | 0.30% min |

Results

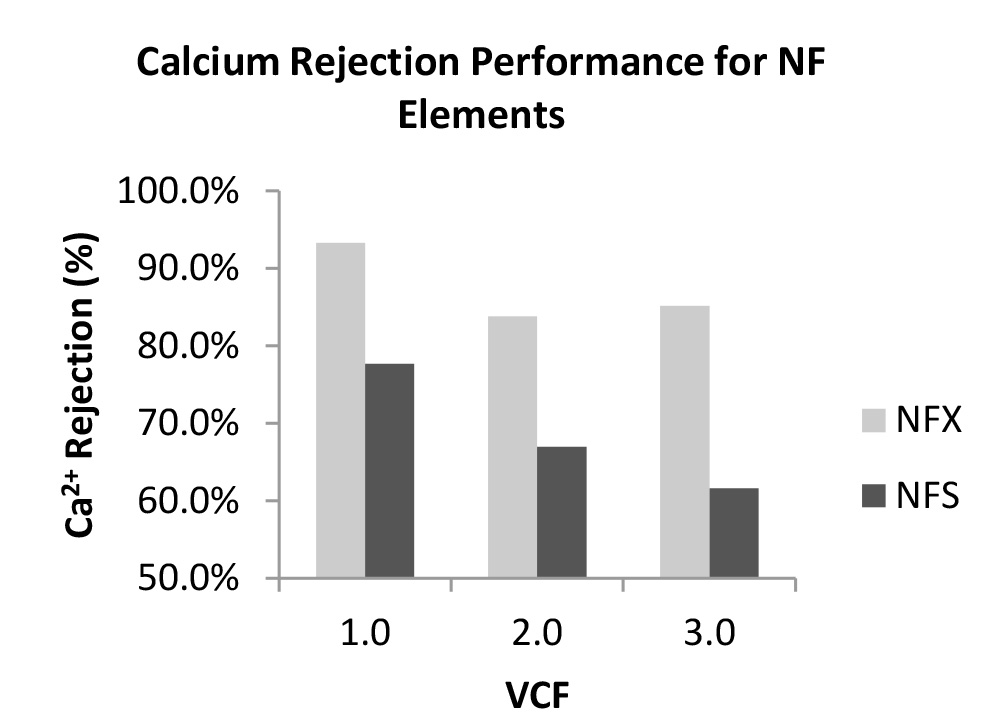

Figure 1: Calcium rejection performance for Synder’s NFX and NFS 2540 elements obtained up to 3x VCF.

Figure 1: Calcium rejection performance for Synder’s NFX and NFS 2540 elements obtained up to 3x VCF. Conclusion

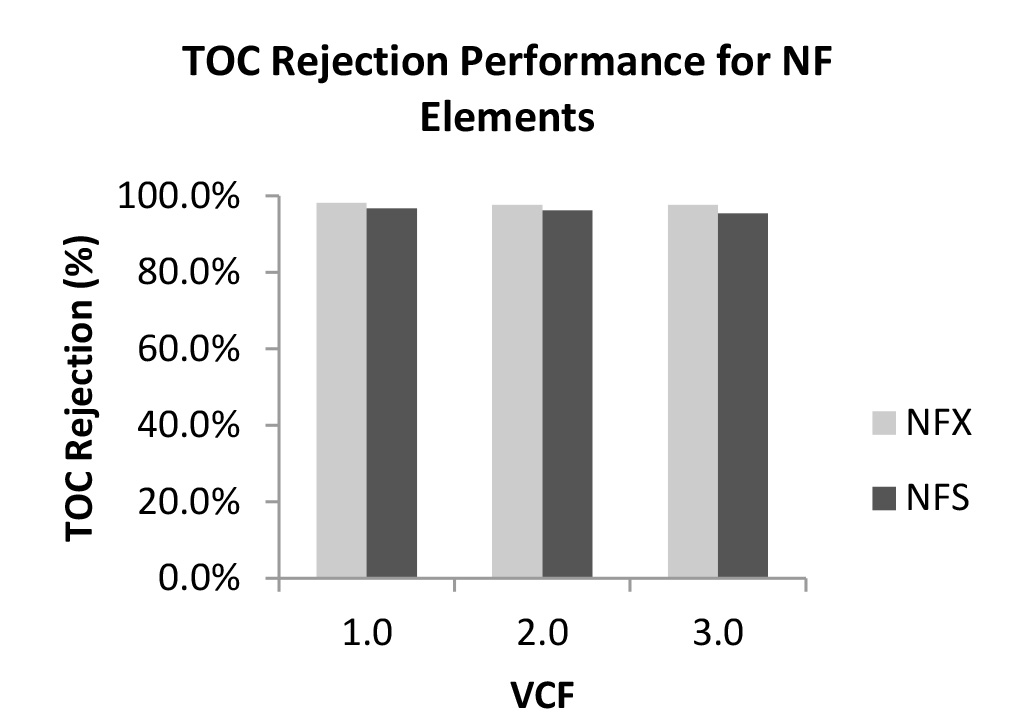

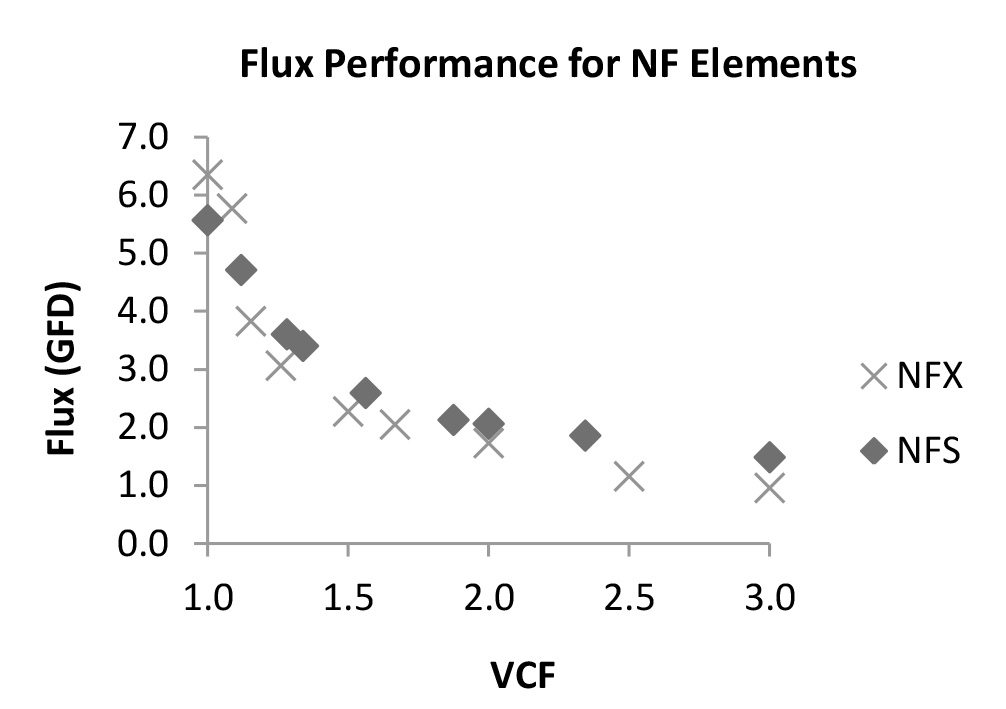

The results of this study indicate that Synder’s NFS membrane has an advantage over NFX in de-ashing capabilities in a feed stream comprised of acid whey powder. Though the permeate flux reached similar values by the end of the run, there was a slight difference in the overall flux decay. NFS exhibited a flux decay of approximately 73%, compared to NFX, which exhibited a flux decay of nearly 85%. There was also a comparable TOC rejection for both membrane types.

Most notably, there was a significant difference in calcium rejection performance between NFX and NFS at each concentration factor, which is beneficial in the production of higher-quality lactose. Overall, these results indicate that Synder’s NFS membrane has the potential to be used for whey concentration, decalcification, and de-ashing applications.

questions? Fill out this form. We’ll contact you within 24 hours!

CASE STUDY

SEAWATER SULFATE REMOVAL

As global demand rises, nanofiltration technology has become essential throughout the oil and gas industry by improving the efficiency of waterflooding… //READ MORE

Applications

Resources

MEMBRANE RESOURCES

- Definition of a Membrane

- Membrane Materials: Organic vs. Inorganic

- Pressure-Driven Membrane Filtration Processes

- Concentration Polarization in Pressure-Driven Processes

- Degrees of Membrane Separation

- Flux Behavior in Membrane Processes

Module Configurations & Processes

-> View all membrane resourcesTUTORIALS