Recovery of Optical Brightening Agents (Textile Industry)

Download Full Case StudyBackground

Optical brightening agents are special dyes that absorb ultraviolet light and re‐emit light in the blue region, usually at 420‐470nm. This application is called the “whitening effect”, which is commonly used to enhance the appearance of certain colors without the damaging effects of bleaching. By increasing the amount of blue light reflected, yellow tones appear whiter. Membrane technology can be applied to capture and concentrate the optical brightening agent for reuse to lower the operating cost in textile and paper industries. Membrane technology provides a process of simultaneous concentrating and desalinating dye solution and thus obtaining concentrated dye with low salt content.

Feed Solution, Membrane, & Operating Conditions

An optical brightening agent was used to test the feasibility of using Synder’s NFX nanofiltration membrane to concentrate the dye for reuse.

Membrane Type & Feed Conditions

| Feed Solution | |

| Material | Optical Brightening Agent |

| Molecular Weight (Da) | 430 |

| Dye Manufacturer | JiNing XinHui Chemical Industry CO. LTD. |

| Conductivity (µs/cm) | 11.1 x 104 |

| Membrane | |

| Element | NFX-2-2540HF |

| Spacer Size (mil) | 31 |

| Surface Area (sq. ft) | 28 |

| Operating Parameters | |

| Element Inlet Pressure (PSI) | 115 |

| Pressure Drop (PSI) | 15 |

| Temperature (°F/°C) | 95/35 |

| Crossflow rate (GPM) | 5 |

| Run time (min) | 38 |

| Feed volume (Gal) | 14.5 |

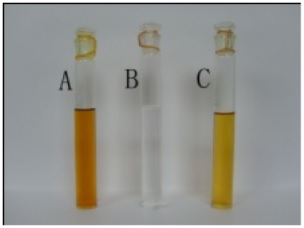

Comparison between the concentrate (A), permeate (B) and feed solution (C) at the end of the experiment

Comparison between the concentrate (A), permeate (B) and feed solution (C) at the end of the experimentTest Results

In a 38 minute batch process, the initial volume of 14.5 gallons was concentrated to 6.9 gallons while achieving a rejection rate of greater than 99%. The effectiveness of the NFX membrane in concentrating this dye is represented visually in a side-by side comparison (Picture 1), where the difference between permeate (B) and concentrate solution (A) is clear. The results of the filtration are summarized in table 2.

| Results | |

| Dye Rejection | >99% |

| Concentrate Volume (Gal) | 6.9 |

| Average Permeate Flux (GFD) | 9.4 |

| Conductivity (concentrate, µs/cm) | 12.5 × 104 |

| Conductivity (permeate, µs/cm) | 9.7 × 104 |

| Overall salt rejection (final) | 22.4% |

Conclusions

Synder’s NFX membrane is very effective in concentrating the optical brightening agent. The average permeate flux is 9.4 GFD, while exhibiting a 49% decline over the entire batch process. Through a comparison of the conductivity of the permeate and concentrate, the salt species in the dye solution seems to pass through the NFX membrane easily. This low salt rejection is ideal to improve the quality of dye solution during the concentration process. Thus, the implementation of the NFX membrane can potentially reduce the capital costs associated with textile manufacturing and give plants an increased ability to meet discharge regulations.

questions? Fill out this form. We’ll contact you within 24 hours!

CASE STUDY

SEAWATER SULFATE REMOVAL

As global demand rises, nanofiltration technology has become essential throughout the oil and gas industry by improving the efficiency of waterflooding… //READ MORE

Applications

Resources

MEMBRANE RESOURCES

- Definition of a Membrane

- Membrane Materials: Organic vs. Inorganic

- Pressure-Driven Membrane Filtration Processes

- Concentration Polarization in Pressure-Driven Processes

- Degrees of Membrane Separation

- Flux Behavior in Membrane Processes

Module Configurations & Processes

-> View all membrane resourcesTUTORIALS