Natural Dissolved Organic Matter Recovery

Download Full Case StudyBackground

Surface water may have high levels of dissolved organic matters (DOM) in many parts of the world. In many cases, DOM must be removed via chemical flocculation and/or coagulation from water before use. With the help of nanofiltration technology, DOM can also be separated and purified into a natural additive for fertilizers to improve the structure of soil and enhance the nutrient acceptance level by a wide variety of plants.

In this specific case, a customer was seeking an energy-saving technology to concentrate the DOM from a swamp in Georgia. Obviously, the more concentrated the humic acid is in the final product, the higher the value and the greater the savings in transport costs. Synder’s NFX membrane was tested in a two month field trial and resulted in a concentration factor of up to 100x, making NF technology a viable solution to achieve the concentration goal.

Membrane and Testing Conditions

| Feed Conditions (River) | |

| Conductivity (us/cm) | 85 |

| pH | ~6 |

| Absorption w/o pH adjustment | 0.516 |

| Turbidity | 2.82 |

| Beginning volume (gal) | 600 |

| Synder Membrane | |

| Element | NFX-2-2540 HM Spiral Element |

| Membrane | Polyamide-TFC |

| NF Standard Operating Parameters | |

| Crossflow (gpm) | 5 gpm |

| Operating pressure (psi) | 210 psi |

| Pressure drop (psi) | 5 psi |

| Wavelength with UV-Vis | 420 nm |

The flux and salt rejection were plotted as a function of concentration factor in the following figures. The concentration factor and salt rejection were calculated as

CF=(absoprtion of feed during concentration process )/(absoprtion of feed at at time 0 )

Rejection = (1-(salt concentration in permeate)/(salt concentration in feed))*100%

Results:

The NFX permeate was plotted over the course of concentration from concentration factor of 1 to 125. The initial permeate flux was at 55 gfd, and the permeate flux at a concentrate factor of 116 was 15 gfd. The overall flux declined 70%, but the flux was highly recoverable via cleaning with acid cleaner and alkaline detergent.

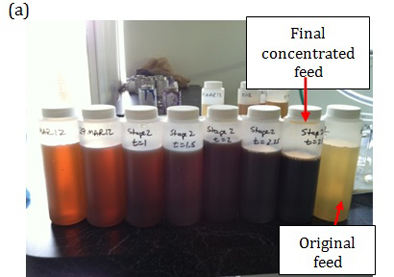

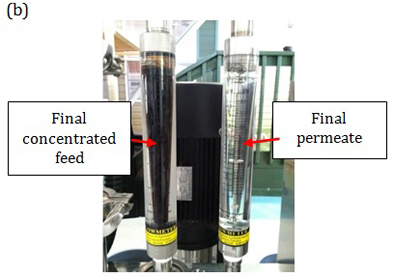

The pictures (a) and (b) show that NFX membrane is able to concentrate the materials progressively and the permeate appears to be clean even when the product was highly concentrated by more than 100 fold.

Summary:

Based on the information obtained from the pilot test, there are some clear advantages of membrane technology over resin adsorption technology:

- NFX membrane filtration is able to concentrate the products by 100x without adding a single chemical into the product

- The resulting pH of the concentrated product is close to neutral (pH ~7), which is desirable for the application without further pH adjustment

- The NFX membrane experienced moderate fouling but was easily recovered to near original flux rates via standard cleaning procedures. Furthermore, the cleaning agents are easily removed by flushing the membrane and system with clean water.

questions? Fill out this form. We’ll contact you within 24 hours!

CASE STUDY

SEAWATER SULFATE REMOVAL

As global demand rises, nanofiltration technology has become essential throughout the oil and gas industry by improving the efficiency of waterflooding… //READ MORE

Applications

Resources

MEMBRANE RESOURCES

- Definition of a Membrane

- Membrane Materials: Organic vs. Inorganic

- Pressure-Driven Membrane Filtration Processes

- Concentration Polarization in Pressure-Driven Processes

- Degrees of Membrane Separation

- Flux Behavior in Membrane Processes

Module Configurations & Processes

-> View all membrane resourcesTUTORIALS