Brine Clarification

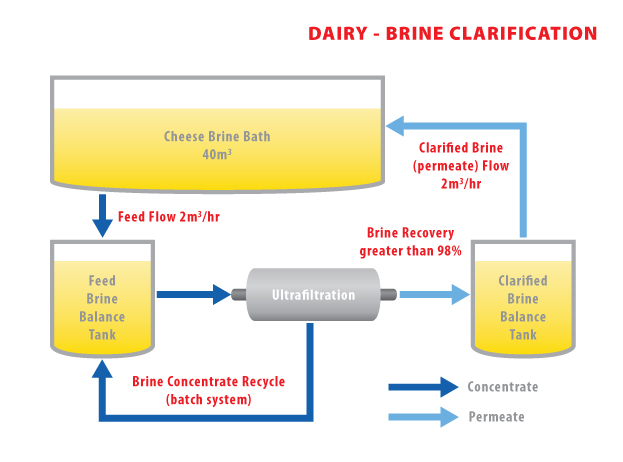

Ultrafiltration can be used to clarify brine solutions generated during the curing of cheese, which can help save costs through the reuse of the solution over multiple batches of cheese. Synder’s BN (PVDF 50) membrane is able to clarify these solutions well, in addition to provide an ion balance that allows cheese to cure at an optimal rate.

Benefits of using membrane process:

- Improve cheese shelf-life by reducing the amount of yeast and mold cells in the brine solution

- Minimize waste effluent requiring treatment

- Reduce costs and maintenance of systems

In the production of cheese, salt brining is used to inhibit bacterial growth and add flavor to the cheese itself. Filtration allows for most of the lactose to be removed for ideal curd ripening, and salting draws moisture from the cheese in order to form the rind and prevent the growth of molds. As the need for waste effluent disposal continues to rise, the use of brine clarification through ultrafiltration has becoming increasingly important to minimize costs and reduce environmental footprints.

Recommended membrane:

BN (PVDF 50)Applications

CASE STUDY

questions? Fill out this form. We’ll contact you within 24 hours!

Resources

MEMBRANE RESOURCES

- Definition of a Membrane

- Membrane Materials: Organic vs. Inorganic

- Pressure-Driven Membrane Filtration Processes

- Concentration Polarization in Pressure-Driven Processes

- Degrees of Membrane Separation

- Flux Behavior in Membrane Processes

Module Configurations & Processes

-> View all membrane resourcesTUTORIALS