Fat/Microbial Removal

Synder’s FR (PVDF 800), V0.1 (PVDF 0.1um) & V0.2 (PVDF 0.2um) microfiltration membranes, can be used as the final fat and microbial removal stage in the production of milk in order to produce high quality WPC and WPIs. Our UF systems are able to operate at lower pressures and are typically less expensive to build and operate compared to ceramic membrane systems.

Benefits using membrane process:

- Extend shelf-life of milk products

- Produce high-quality WPC/WPI

- Efficiency at low operating pressures

With the largest pore size range, microfiltration is commonly used to extend the shelf-life of milk and produce high-quality milk products. It is especially applicable for use of bacteria and spore removal when treatment options involving high temperature conditions are not suitable. This process can be used as a pretreatment step to pasteurization to ensure that all vegetative spores are completely removed from the milk.

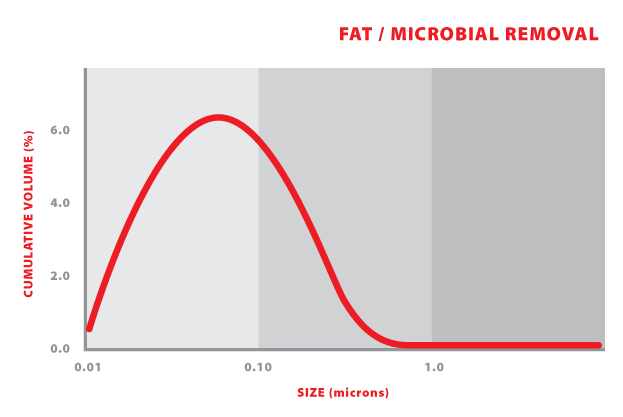

Figure: Indication of colloid size distribution in milk sample (cumulative volume (%) vs. size (micron))

Recommended membrane:

FR, V0.1, V0.2Applications

CASE STUDY

questions? Fill out this form. We’ll contact you within 24 hours!

Resources

MEMBRANE RESOURCES

- Definition of a Membrane

- Membrane Materials: Organic vs. Inorganic

- Pressure-Driven Membrane Filtration Processes

- Concentration Polarization in Pressure-Driven Processes

- Degrees of Membrane Separation

- Flux Behavior in Membrane Processes

Module Configurations & Processes

-> View all membrane resourcesTUTORIALS