NFX Membrane for Wastewater Processing in Paper Production

The pulp and paper industry requires the use of large volumes of clean water in order to process the wood shavings used to convert pulp into paper. The harsh chemicals used to treat the wood post a hazard to the environment, if the toxic waste is discharged. With the use of membrane technology, the wastewater is able to be purified into water that is suitable for reuse in the paper-making process which minimizes the environmental impact and can save manufacturers both time and money.

Benefits of membrane process:

- Reduction of fresh water intake

- Recycling of treated effluent for reuse in production of paper

- Minimization of environmental impact

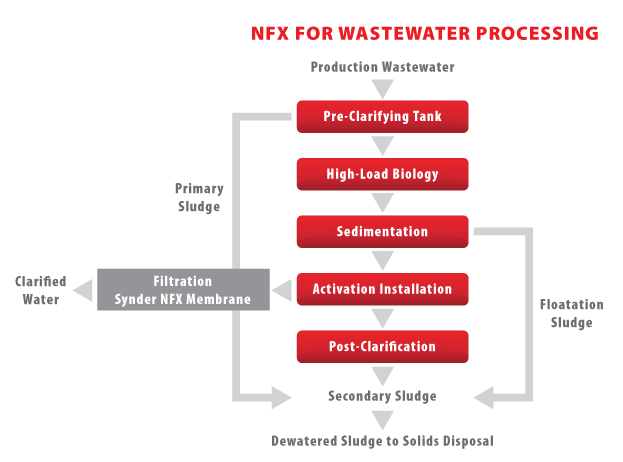

Synder Filtration’s NFX nanofiltration membrane is able to process the toxic wastewater containing the harsh chemicals used in the pulp and paper mills. With small pore size ranges and partial rejection of multivalent ions, nanofiltration has become an alternative for purifying wastewater and effluents for reuse in the pulp and paper industry. With the addition of pre-treatment or in conjunction to ultrafiltration, the NF membrane units are able to withstand high strength organic and inorganic compounds, purifying the water so that is available for reuse in paper production.

Recommended membranes:

NFX & NFW