![]() Electrocoat Industry

Electrocoat Industry

A62-1812TM Specsheet

With over 20 years of experience in the ECoat industry, Synder Filtration has proven to be one of the top suppliers of membrane technology when it comes to Ultrafiltration elements, anode cells, and EDUF systems. As a manufacturer of both custom membranes and systems, we strive to provide quality products and reliable service for our customers around the world. With a full range of molecular weight cutoffs and element sizes for both cathodic and anodic paint baths, Synder can easily outfit any ECoat paint line with reliable ultrafiltration membrane elements.

A6 has the largest pore size of all the ultrafiltration membranes, with a molecular weight cut-off of 500kDa. While V6 is used for cathodic electrocoat paint recovery, A6 has the same pore size but is used for anodic electrocoat paint recovery, surfactant cleanup and recovery, and mine wastewater reuse. This membrane is also suitable for applications involving fat and microbial removal. Along with the other membranes, A6 is available in flat sheet, standard spiral-wound elements, and custom configurations upon request.

INDUSTRIAL SERIES BENEFITS

- Widest range of UF MWCO’s available

- Good resistance to pH and temperature

- High resistance to fouling

- Customizable dimensions for unique housings

COMMON APPLICATIONS

- Anodic electrocoat paint

- Microbial/Particle removal

Element Specifications

RECOMMENDED OPERATING PARAMETERS

| Membrane Type | |

| Proprietary PVDF | Spiral-Wound with netted outerwrap or fiber glass hardshell (FRP) |

| Pressure | PSI | Bar |

| Max Inlet Pressure | 116 | 8.0 |

| Min Outlet Pressure | 10 | 0.7 |

| Max Differential Pressure per Element | 18 | 1.2 |

| Max Permeate Backpressure | 5 | 0.3 |

Note: Soft start on boost pumps required to minimize pressure/flow shocks to elements.

| Temperature | Fahrenheit | Celsius |

| Max. Operating | 122° | 50° |

| Max. CIP Temperature | 122° | 50° |

| pH Parameters | pH |

| pH Range during Operation at 25°C Max | 1.0-11.0 |

| pH Range during CIP Operation at 50°C Max | 2.0-11.0 |

| Peroxide | Max ppm. |

| Free Peroxide in Product During Operation | <3 ppm |

| Peroxide as a sanitizer at 25°C Max, pH6-7, 10minutes recirculation | 0.1% |

| Chlorine | Norm PPM | Max PPM |

| Free Chlorine During Operation | 0 | <0.1 |

| Chlorine During CIP at pH10.8-11.0 and 50°C | 150 | 180 |

Note: Maximum chlorine exposure for all elements is 30 minutes per day at pH and temperature conditions listed above.

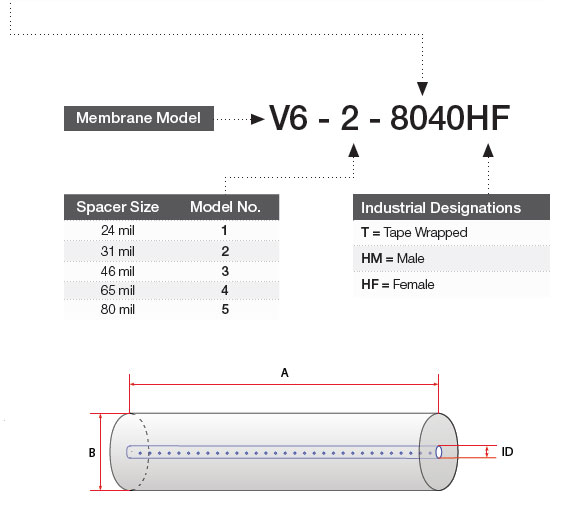

DIMENSIONS & WEIGHT

| Element | Model No. | Diameter (B) in (cm) | Length (A) in (cm) | PWT ID/OD in (cm) | Tube Extension (C) in (cm) | Dry Weight lb (kg) |

| 1.8" | 1812TM | 1.8” (4.6) | 11.75” (29.8) | 0.665” (1.71) | 0.75” (perm) 1.00” (plug) |

1.0 (.45) |

| 2.5" | 2540TM 2540HF 2540HM |

2.4” (6.1) 2.4” (6.1) 2.4” (6.1) |

40.0” (101.6) 40.0” (101.6) 40.0” (101.6) |

0.75” (1.90) 0.625” (1.59) 0.75” (1.90) |

1.00” (2.54) – 1.00” (2.54) |

4.0 (1.8) 4.0 (1.8) 4.0 (1.8) |

| 4" | 4040TM 4040HM 4040HF |

3.9” (9.9) 3.9” (9.9) 3.9” (9.9) |

40.0” (101.6) 40.0” (101.6) 40.0” (101.6) |

0.75” (1.90) 0.75” (1.90) 0.625” (1.59) |

1.00” (2.54) 1.00” (2.54) – |

12.0 (5.5) 12.0 (5.5) 12.0 (5.5) |

| 8" | 7940HF 8040HF |

7.9” (20.1) 7.9” (20.1) |

40.0” (101.6) 40.0” (101.6) |

1.138” (2.89) 1.125” (2.86) |

– – |

35.0 (15.9) 35.0 (15.9) |

Recommended Element Cross Flow Rate

| Element | Feed Spacer (in miles)

|

||||||||||

| 1.8" | m3/hr gpm |

0.7 3 |

0.8 3 |

0.9 4 |

1.0 4 |

1.1 5 |

|||||

| 2.5" | m3/hr gpm |

1.3 6 |

1.5 7 |

1.8 8 |

2.0 9 |

2.1 9 |

|||||

| 4.0" | m3/hr gpm |

3 15 |

4 17 |

5 20 |

5 23 |

5 24 |

|||||

| 8" | m3/hr gpm |

15 66 |

17 75 |

20 89 |

23 99 |

24 105 |

|||||

*Note: The recommended cross flow rate will be subject to differential pressure limitations and specific applications.

Membrane Area(SQ. FT.)

| Element | Feed Spacer (in mils)

|

|||||||||

| 1812TM | 3.1 | 2.7 | 2.1 | 1.6 | 1.3 | |||||

| 2540M | 28 | 24 | 20 | 16 | 13 | |||||

| 2540F | 30 | 26 | 22 | 17 | 14 | |||||

| 4040M | 81 | 72 | 58 | 46 | 39 | |||||

| 4040F | 86 | 75 | 61 | 49 | 41 | |||||

| 7940F | 379 | 335 | 268 | 210 | 178 | |||||

| 8040F | 379 | 335 | 268 | 210 | 178 | |||||

TECHNICAL NOTES

For element sizes not listed, please call or email Synder Filtration for details. We can design an element to fit your exact needs – just specify the element outer diameter (OD) or vessel/housing inner diameter (ID), element inner diameter (ID), and length. Elements are also available with or without a controlled bypass tail. Additional feed spacers are also available. Trials should be conducted to determine optimal application conditions.

Applications

Similar Membranes

questions? Fill out this form. We’ll contact you within 24 hours!

Resources

MEMBRANE RESOURCES

- Definition of a Membrane

- Membrane Materials: Organic vs. Inorganic

- Pressure-Driven Membrane Filtration Processes

- Concentration Polarization in Pressure-Driven Processes

- Degrees of Membrane Separation

- Flux Behavior in Membrane Processes

Module Configurations & Processes

-> View all membrane resourcesTUTORIALS