NFS Sulfate Removal Membrane

NFSTM – Synder’s New Nanofiltration Thin-film Composite Membrane Ideal for Sulfate Removal Applications

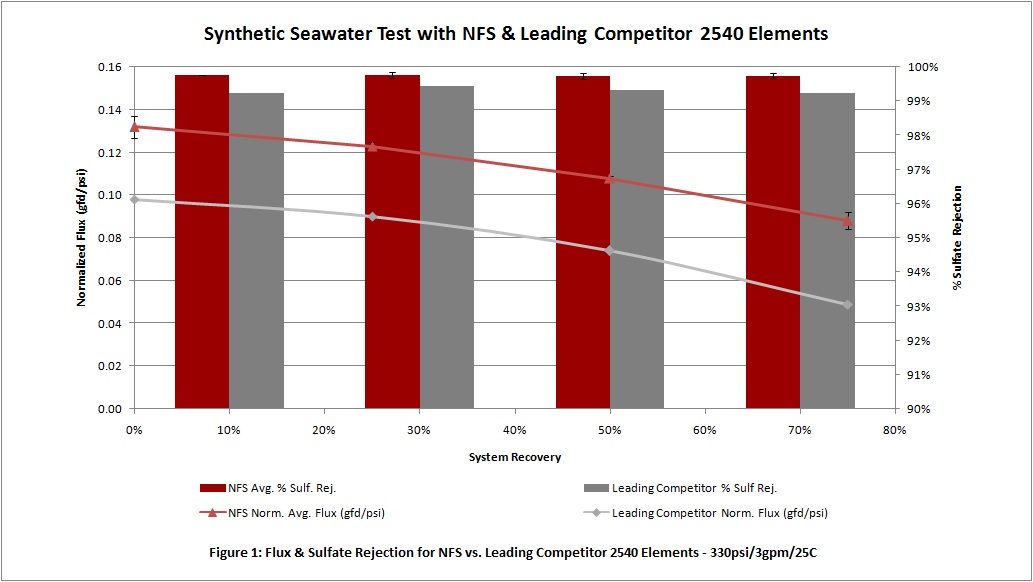

Synder Filtration is pleased to introduce NFSTM, a nanofiltration membrane specifically formulated to deliver superior sulfate rejection for applications such as water flood injection in the oil and gas industry. This membrane consistently produces greater flux vs. leading competitors, increasing efficiency and potentially reducing NF system footprint on offshore platforms.

Background

Sulfate plays a major role in limiting oil recovery of by way of scaling caused by the precipitation of both barium sulfate and strontium sulfate. Additionally, sulfate serves as a primary source of sulfur in the formation of hydrogen sulfide, which results in oil well souring. As a result, several water treatment steps are necessary in order to minimize sulfate concentration prior to injection.

Nanofiltration is well-suited for the mitigation of scaling and souring caused by sulfate ions, due to the high rejection of divalent ions, like sulfate. Synder Filtration’s NFSTM membrane allows for greater efficiency in flux and rejection than ever before.

| Model | Polymer | Approx. Molecular Weight Cutoff |

Typical Operating Flux1 | Avg Na2SO4 Rejection | Min MgSO4 Rejection1 | Average NaCI Rejection3 |

| NFS | Proprietary PA TFC | 100-250Da | 30-40 GFD | 99.7% | 99.5% | 50-55% |

1Test Conditions: 2,000ppm MgSO4 solution at 110PSI (760 kPa) operating pressure, 77° F (25° C)

2Test Conditions 2,000ppm Na2SO4 Solution at 110PSI (760 kPa) operating pressure, 77° F (25° C)

3Test Conditions 2,000ppm NaCI Solution at 110PSI (760 kPa) operating pressure, 77° F (25° C)

Synthetic Seawater Testing

NFSTM demonstrates superior sulfate rejection and flux performance versus leading competitors when tested with ASTM synthetic seasalt. In addition, the membrane exhibits a high-degree of mechanical strength, as well as excellent pH, temperature, and fouling resistance.

For additional information regarding the NFS membrane, please contact us for more information. You will receive a personal response from one of our experienced team members within 24 hours.

CASE STUDY

Applications

questions? Fill out this form. We’ll contact you within 24 hours!

Resources

MEMBRANE RESOURCES

- Definition of a Membrane

- Membrane Materials: Organic vs. Inorganic

- Pressure-Driven Membrane Filtration Processes

- Concentration Polarization in Pressure-Driven Processes

- Degrees of Membrane Separation

- Flux Behavior in Membrane Processes

Module Configurations & Processes

-> View all membrane resourcesTUTORIALS