Tubular membranes

Description

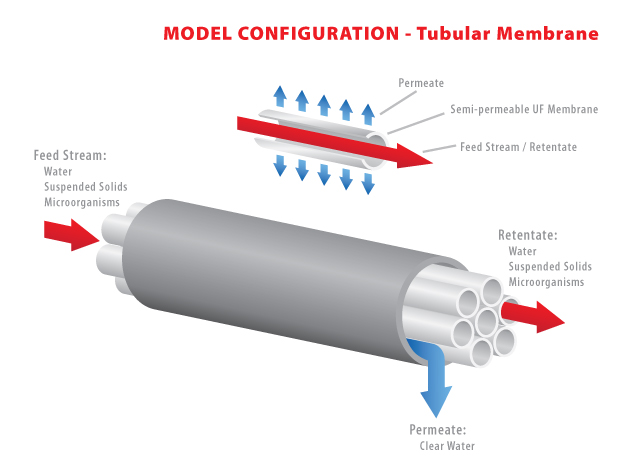

Tubular membrane modules are tube-like structures with porous walls. Tubular modules work through tangential crossflow and are generally used to process difficult feed streams such as those with high dissolved solids, high suspended solids, and/or oil, grease, or fats. They typically have ½” to 1” OD tubes that are packed individually into a long PVC housing and can be either polymer- or ceramic-based.How it works

Tubular modules consist of a minimum of two tubes; the inner tube, called the membrane tube, and the outer tube, which is the shell. The feed stream goes across the length of the membrane tube and is filtered out into the outer shell while concentrate collects at the opposite end of the membrane tube. They are commonly used for applications such as oily wastewater treatment, MBR and other high solids processes.Disadvantages

Low packing density and large size are disadvantages of tubular modules. Packing density of tubular modules is higher than plate and frame systems but lower than capillary, hollow fiber, and spiral wound elements. Because of the large inner diameter of the tubular modules, flow requirements are higher than those of other system configurations. The capital and operating costs (pump energy) for tubular membranes tends to be very high, along with the requirements for larger footprints for capital equipment.Advantages

Tubular systems have less fouling compared to plate and frame systems, and a similar amount of fouling when compared to spiral and capillary. Tubular systems allow for robust cleaning methods such as the use of harsh chemicals, backwash, and even mechanical cleaning which might not be available for other system configurations. They can handle the highest solids and emulsified oil load compared to many other membrane types and can be physically cleaned with sponge balls.

*Please note that Synder Filtration only offers flat sheet and spiral-wound element configurations. The information above is for comparison purposes only. Please contact us at sales@synderfiltration.com or 7077-451-6060 for more information on pricing and availability.

CASE STUDY

Applications

Resources

MEMBRANE RESOURCES

- Definition of a Membrane

- Membrane Materials: Organic vs. Inorganic

- Pressure-Driven Membrane Filtration Processes

- Concentration Polarization in Pressure-Driven Processes

- Degrees of Membrane Separation

- Flux Behavior in Membrane Processes

Module Configurations & Processes

-> View all membrane resourcesTUTORIALS