Microfiltration Membrane Filters

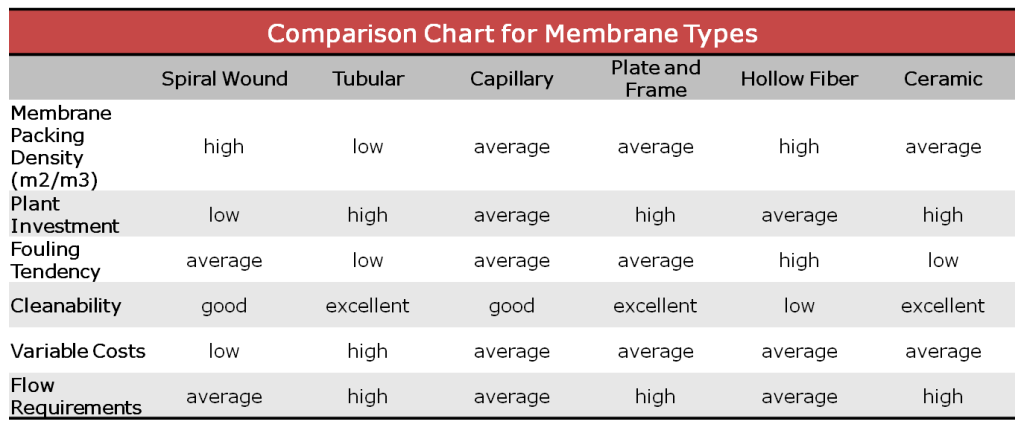

Microfiltration is a low pressure separation process utilizing membranes with very open pore structures. Microfiltration filters can be made in both organic materials, such as polymer based membranes, as well as inorganic materials, such as ceramic or stainless steel. In selecting the appropriate membrane configuration, spiral-wound polymeric MF filters are often the starting point for consideration based on spiral MF’s balance of durability, membrane area per unit, and significantly lower membrane unit cost, and equipment capital cost vs. ceramic and stainless.

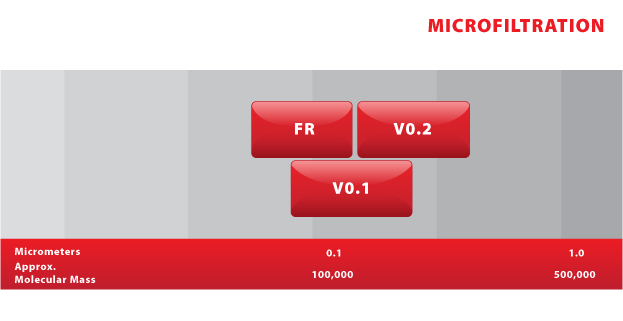

With a pore size range of 0.1 to 10μm, microfiltration membranes are capable of separating large suspended solids such as colloids, particulates, fat, and bacteria, while allowing sugars, proteins, salts, and low molecular weight molecules pass through the membrane.

Synder Filtration currently offers three types of polymeric microfiltration filters, all of which maintain good resistance to pH, temperature, and fouling tendencies. They are also commonly used as a pretreatment step for feed stream applications.

Applications of Synder’s MF membrane technology include:

- Fat / microbial removal in Whey Protein Concentrate / Isolate

- Casein / Whey fractionation

- Clarification of fermentation broths

- Microbial removal, clarification

- Plant extract clarification

- Gelatin clarification

- Wine clarification

- Corn wet milling

- Industrial process wastewater treatment

Synder offers a comprehensive application development program as well as microfiltration membrane development in certain cases. Please contact us for more information. You will receive a personal response from one of our experienced team members within 24 hours!