What are Nanofiltration Membranes?

Intro

Synder Filtration offers a suite of nanofiltration membranes that are engineered to provide optimal flux and rejection and can be customized to meet the unique requirements of specific process applications. Available in both spiral-wound and flat sheet formats, Synder’s NF membranes are capable of rejecting multivalent salts and larger molecules, while selectively rejecting varying amounts of monovalent salts.

Overview

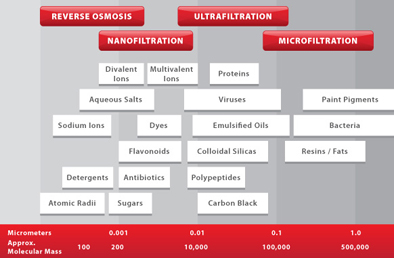

Nanofiltration is a separation process characterized by organic, thin-film composite membranes with a pore size range of 0.1 to 10nm. Unlike RO membranes, which reject all solutes, NF membranes can operate at lower pressures and offer selective solute rejection based on both size and charge.

Degrees of Separation

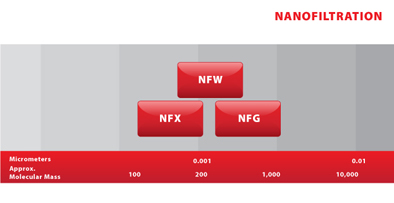

Synder Filtration’s wide range of NF membranes offer varying degrees of ion selectivity to aid in the development of customized process solutions. Synder’s sanitary NF membranes are compliant with FDA standards listed in CFR Title 21, 3-A Sanitary Standards No. 45-02, as well as USDA sanitary standards and are fit for use in a variety of sanitary, as well as industrial applications across a broad spectrum of industries. If required, Synder can even develop new nanofiltration membrane materials to meet specific process goals, in partnership with our customers.

NF Products

With a pore size between 0.1-10nm, Synder Filtration’s nanofiltration filters will allow water and some salts to pass through the membrane while retaining multivalent ions, low molecular weight molecules, sugars, proteins, and other organic compounds. After years of research and development, Synder’s NFX, NFW, and NFG nanofiltration membrane product line have been proven to offer great resistance to fouling, a high degree of selectivity, and the physical durability needed for application in a wide range of industrial separation processes. NFX and NFW have excellent MgSO4 and lactose rejection, while NFG partially removes monosaccharides from oligosaccharides. NF membranes overall are also able to greatly reduce levels of hardness, nitrates, sulfates, tannins, turbidity, color, TDS, and moderate levels of salt from feed water streams.

| Model | Polymer | Approx. Molecular Weight Cutoff |

Typical Operating Flux1 | Min Lactose Rejection2 | Min MgSO4 Rejection1 | Average NaCI Rejection3 |

| NFX | Proprietary PA TFC | 150-300Da | 20-25 GFD | 99.0% | 99.0% | 40.0% |

| NFW | Proprietary PA TFC | 300-500Da | 45-50 GFD | 98.5% | 97.0% | 20.0% |

| NFG | Proprietary PA TFC | 600-800Da | 55-60 GFD | 60.0% | 50.0% | 10.0% |

1Test Conditions: 2,000ppm MgSO4 solution at 110PSI (760 kPa) operating pressure, 77° F (25° C)

2Test Conditions 2,000ppm Lactose Solution at 110PSI (760 kPa) operating pressure, 77° F (25° C)

3Test Conditions 2,000ppm NaCI Solution at 110PSI (760 kPa) operating pressure, 77° F (25° C)

NF Applications

Nanofiltration membranes are a relatively recent development, and offer greater selectivity of ions vs. reverse osmosis membranes that reject all ion species in a feed stream. This unique characteristic provides flexibility in separation process development that can greatly impact performance and profitability, especially for industrial applications.Here are some common applications of Synder’s NF membrane technology:

Dairy

- Lactose and whey demineralization in dairy processing

Industrial/Wastewater Treatment

- Removal of natural organic matter in water and wastewater treatment

- Reduction of hardness in water purification

- Sulfate removal from seawater and chemical processes

- Desalting of process streams in various industries

Synder offers a comprehensive application development program and even nanofiltration membrane development may be available upon request. Please contact us for more information. You will receive a personal response from one of our experienced team members within 24 hours.