Nanofiltration Membrane Systems: Pilot & Full Scale

Nanofiltration systems are very similar in design to reverse osmosis systems, but can be operated with lower pressure and may require more customized features to meet specific process application requirements.

Synder Filtration designs and fabricates a wide range of nanofiltration systems, but we also help customers to develop processes through our unique and collaborative application development program.

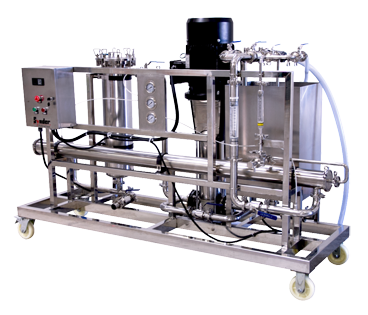

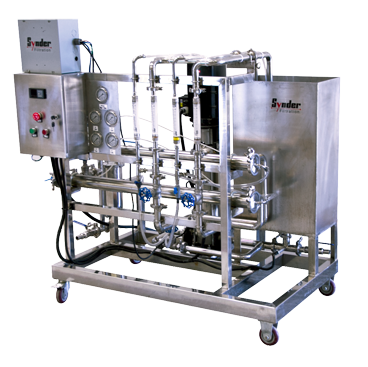

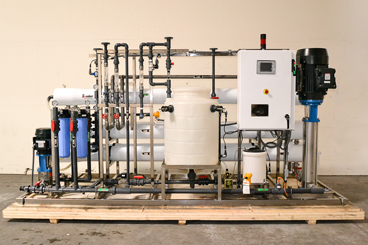

We start by meeting with our customers to gain an understanding of their process goals. Synder’s development team then prepares a comprehensive test plan, including feasibility and pilot scale testing. Synder offers a wide array of nanofiltration pilot systems with a full range of capabilities. Some of NF pilot systems are mini-production demonstration units. See below for some examples of nanofiltration pilot units and full-scale systems.

With operating pressures up to 1,000psi and durable SS304 or SS316 stainless steel construction, pilot tests can be performed at the most extreme operating conditions. Pilot studies are conducted either at Synder’s Application Development Center in Vacaville, California, or on location at a customer’s chosen test facility.

Once the test results are collected, the engineering team engages to design the full scale membrane process solution. As a nanofiltration systems manufacturer, Synder has the capability to fabricate, install, commission and support full-scale and multi-process (RO, NF, UF, & MF) membrane systems. In every step of the process, we aim to deliver timely, knowledge, friendly service, and ultimately, application profitability for our customers.

Please contact us to find out more. You will receive a personal response from one of our experienced team members within 24 hours.

CASE STUDY

Applications

questions? Fill out this form. We’ll contact you within 24 hours!

Resources

MEMBRANE RESOURCES

- Definition of a Membrane

- Membrane Materials: Organic vs. Inorganic

- Pressure-Driven Membrane Filtration Processes

- Concentration Polarization in Pressure-Driven Processes

- Degrees of Membrane Separation

- Flux Behavior in Membrane Processes

Module Configurations & Processes

-> View all membrane resourcesTUTORIALS