Nanofiltration: Spiral-Wound Elements

Nanofiltration membranes are available in many different configurations, including hollow fiber, tubular, flat sheet, and spiral-wound. When total suspended solids can be largely removed via prefiltration, Spiral-wound nanofiltration elements are often preferred because they offer a balanced combination of packing density (membrane area vs. module volume), physical durability, membrane life, and unit cost.

Nanofiltration membranes are available in many different configurations, including hollow fiber, tubular, flat sheet, and spiral-wound. When total suspended solids can be largely removed via prefiltration, Spiral-wound nanofiltration elements are often preferred because they offer a balanced combination of packing density (membrane area vs. module volume), physical durability, membrane life, and unit cost.

| Model | Polymer | Approx. Molecular Weight Cutoff |

Typical Operating Flux | Avg Lactose Rejection1 | Avg MgSO4 Rejection2 | Avg NaCI Rejection3 |

| NFS | Proprietary PA TFC | 100-250Da | 30-40 GFD | 99.5% | 99.5% | 50.0% |

| NFX | Proprietary PA TFC | 150-300Da | 20-25 GFD | 99.0% | 99.0% | 40.0% |

| NFW | Proprietary PA TFC | 300-500Da | 45-50 GFD | 98.5% | 97.0% | 20.0% |

| NFG | Proprietary PA TFC | 600-800Da | 55-60 GFD | 60.0% | 50.0% | 10.0% |

1Test Conditions: 2% Lactose solution at 110PSI (760 kPa) operating pressure, 77° F (25° C)

2Test Conditions 2,000ppm MgSO4 Solution at 110PSI (760 kPa) operating pressure, 77° F (25° C)

3Test Conditions 2,000ppm NaCI Solution at 110PSI (760 kPa) operating pressure, 77° F (25° C)

Synder Filtration currently offers three different types of spiral wound nanofiltration elements, available in both sanitary and industrial grades and a variety of sizes. With a molecular weight cut-off between 150-300Da, NFX is the ‘tightest’ of the three with average MgSO4 and lactose rejection of 99%. NFW is the intermediary, with a molecular weight cut-off between 300-500Da and a relatively high MgSO4 and lactose rejection as well. NFG is the most open nano-membrane in the range, with a molecular weight cut-off between 600-800Da.

Synder’s sanitary nanofiltration spiral-wound elements are compliant with FDA (CFR Title 21), 3-A (Sanitary Standards No. 45-02) and USDA sanitary standards and are fit for use in a variety of food & beverage, dairy, and biotech applications. Industrial grade nanofiltration elements are also available.

Synder can customize spiral wound elements and even develop new membranes for specific application processes upon request. Please contact us to find out more. You will receive a personal response from one of our team members within 24 hours.

TECHNICAL NOTES

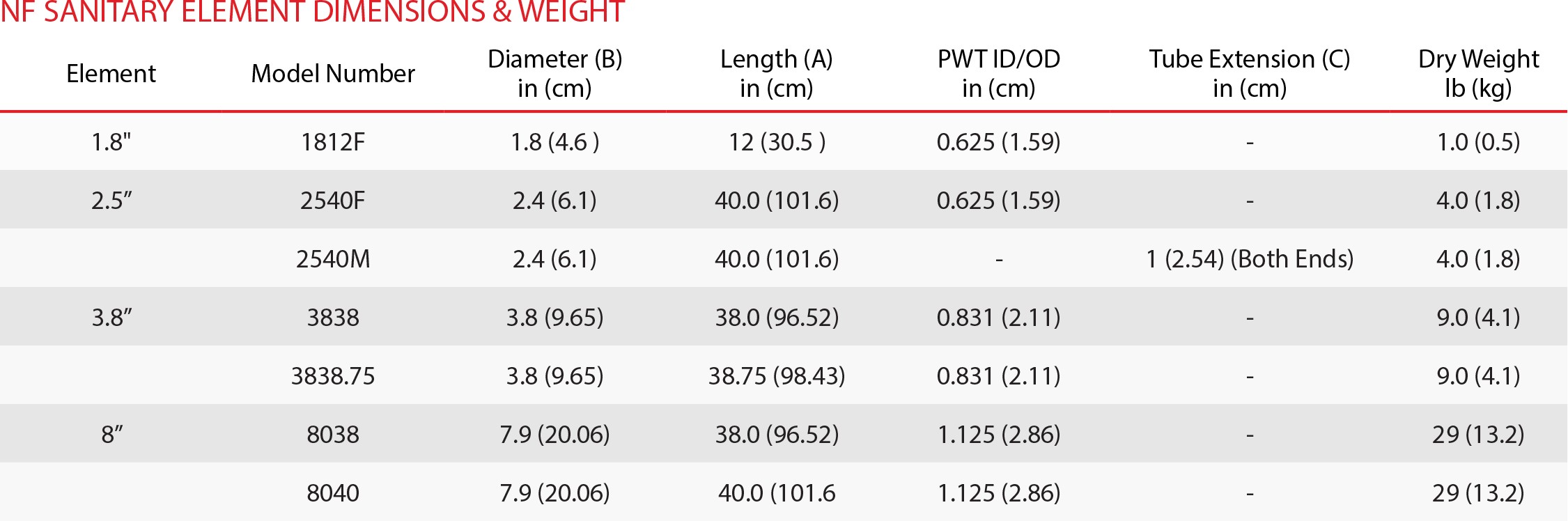

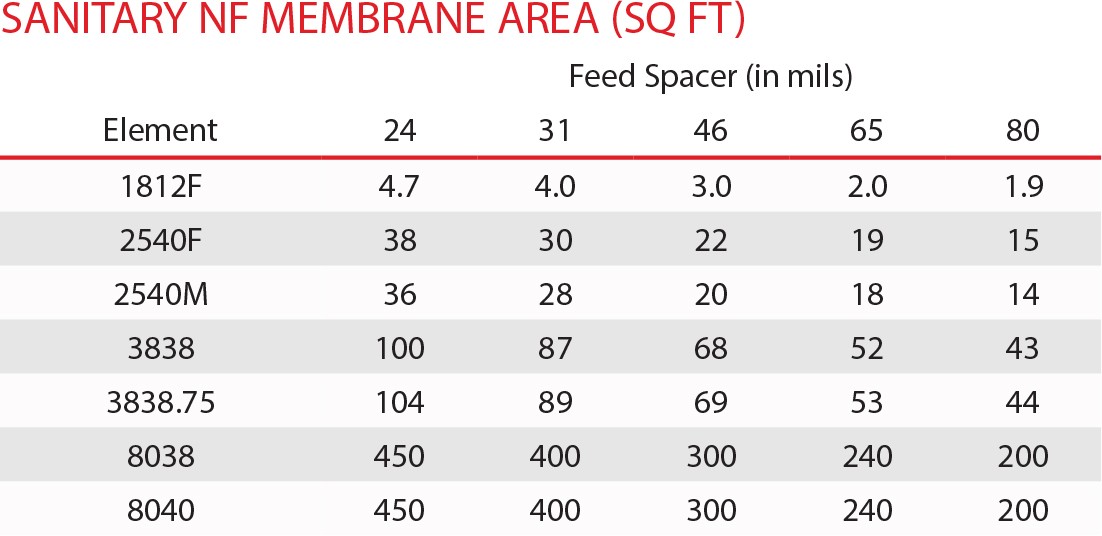

For element sizes not listed, please call or email Synder Filtration for details. We can design an element to fit your exact needs – just specify the element outer diameter (OD) or vessel/housing inner diameter (ID), element inner diameter (ID), and length. Elements are available with or without a controlled bypass tail. Additional feed spacers are also available.

Trials should be conducted to determine optimal application conditions.

Refer to installation, cleaning, and storage procedures for more details.questions? Fill out this form. We’ll contact you within 24 hours!

CASE STUDY

Applications

Resources

MEMBRANE RESOURCES

- Definition of a Membrane

- Membrane Materials: Organic vs. Inorganic

- Pressure-Driven Membrane Filtration Processes

- Concentration Polarization in Pressure-Driven Processes

- Degrees of Membrane Separation

- Flux Behavior in Membrane Processes

Module Configurations & Processes

-> View all membrane resourcesTUTORIALS