Plate and Frame Membranes

Description

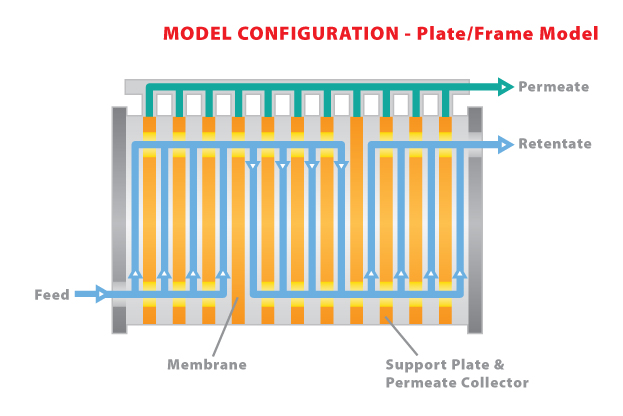

Plate and Frame membrane systems utilize membranes laid on top of a plate-like structure, which in turn is held together by a frame-like support. Flat sheet membranes are bolted together with a frame around the perimeter; similar to a heat exchanger or filter press. There are two types of plate and frame membrane configurations; dead-end and cross flow. In dead-end plate and frame systems, the feed solution flows perpendicular into the membrane, while cross flow systems are made so that the flow is tangential to the membrane wall.How it works

Because the flow is perpendicular to the membrane, dead-end plate and frame membrane separation works through a process called cake filtration. Cake filtration starts when the feed solution passes through the filter plates and creates a buildup of solids on the filter surface. This buildup, or cake layer, reduces the effective pore size opening of the filter and helps improve the filtration of the feed solution.For cross flow plate and frame membrane systems, fouling of the membrane is significantly less because the flow is tangential and does not require use of the cake filtration system. It works on the basic principles of cross flow where feed enters on one side of the plated membrane and concentrate collects on the other end of the plate. Permeate travels through the membrane and collects on the inside of the supporting plate.

Common applications for plate & frame configurations include cosmetics production, MBR, and specialty high solids food and beverage applications.

Disadvantages

Low packing density is one major problem for plate and frame membrane systems. Low efficiency compared to other configurations, and high pressure drop, are other problems that plague plate and frame systems as well. For dead end systems, buildup is much greater than cross-flow systems and therefore efficiency is much less.Irreversible damage is also a common problem because of the constant buildup on the membrane surface.

In addition, plate and frames are difficult and expensive to clean and maintain. Entire racks must be disassembled for replacement and the cost per square meter can be very high.

Advantages

A couple main advantages of plate and frame membrane systems include solids being able to be easily separated from water and easy removal/cleaning of filter surfaces. Certain cross flow plate and frame systems allow the plate and frame to be rotated, allowing more shearing forces and fouling reduction. Plate and frame filters also do not have any feed spacers which reduces the potential for fouling and they can typically handle high solids concentrations

*Please note that Synder Filtration only offers flat sheet and spiral-wound element configurations. The information above is for comparison purposes only. Please contact us at sales@synderfiltration.com or 7077-451-6060 for more information on pricing and availability.

CASE STUDY

questions? Fill out this form. We’ll contact you within 24 hours!

Applications

Resources

MEMBRANE RESOURCES

- Definition of a Membrane

- Membrane Materials: Organic vs. Inorganic

- Pressure-Driven Membrane Filtration Processes

- Concentration Polarization in Pressure-Driven Processes

- Degrees of Membrane Separation

- Flux Behavior in Membrane Processes

Module Configurations & Processes

-> View all membrane resourcesTUTORIALS